A252 Mesh

Material: HRB335, HRB400, HRB400E, HRB500 Carbon Steel

Diameter: 8mm

Delivery Time: 15-21 days

Transportation: By sea, by land

A252 Mesh

A252 mesh is a type of steel mesh made by welding low-carbon steel wires. The mesh is square-shaped and has the characteristics of high tensile strength, corrosion resistance, durability, and convenient construction. It is commonly used in concrete projects such as ground reinforcement, floor slabs, and road paving. When combined with the high tensile strength of concrete, it enhances the concrete structure and reduces cracking. Wanzhi Steel specializes in producing A252 mesh. In addition, we also have commonly used steel mesh such as A393 and A193, which are supplied at factory prices. If you are interested, please feel free to contact us.

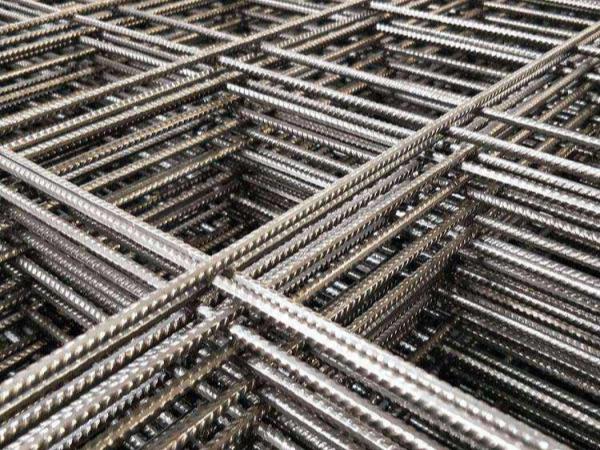

Steel reinforcement mesh surface

A252 Welded Reinforcement Rebar Concrete Mesh

Specification

| Item | A252 Mesh |

| Place of Origin | Shandong, China |

| Standard | AISI, ASTM, DIN, JIS, GB, EN |

| Processing Service | Welding, Cutting, Bending |

| Technique | Hot Ribbed Steel Rebar, prestressed |

| Shape | Straight-bar |

| Hole Shape | Square Hole |

| Surface treatment | Galvanized (Optional) |

| Color | Silver |

| Width | 1.2m, 1.8m, 2.4m, customizable |

| Length | 1-6m, customizable |

| Usage | Road, bridge, and tunnel, building |

| Sample | Free Available |

| Payment term | TT 30% Advance + 70% Balance |

| Price Item | FOB, CIF, EXW, CFR, etc |

| Packing | Bundle or as per your requirements |

| Certification | ISO 9001, SGS, ABS, BV |

| MOQ | 10 tons |

Character definition

Simply put, a252 mesh refers to a welded steel mesh with a weight of 5.95 kilograms per square meter, a nominal diameter of 8 millimeters, and a mesh spacing of 200mm x 200mm.

- A “: A mesh made of welded A-grade steel bars that comply with BS 4483 standard.

- 252 “: represents the nominal cross-sectional area of each linear meter of steel reinforcement, measured in square millimeters (mm ²).

a252 reinforcing mesh Manufacturer

Welded Threaded Concrete Galvanized Rebar Mesh Sheet

Key Features

- Material and Structure: Made of low-carbon steel wire or cold-rolled ribbed steel bars welded together, with longitudinal and transverse steel bars welded at right angles to form a stable grid.

- High tensile strength: The material properties endow it with excellent tensile performance, which can withstand large tensile forces without easily breaking.

- Corrosion resistant and durable: Low carbon steel wire material has a certain degree of corrosion resistance, and the A252 mesh after galvanizing is capable of withstanding humid or corrosive environments, extending its service life.

- Convenient construction: Prefabricated production, direct on-site laying, eliminating the traditional steel bar binding process, greatly improving construction efficiency.

- Enhanced concrete performance: After being combined with concrete, it can effectively disperse stress, reduce the risk of cracking, and improve overall stability and seismic resistance.

Galvanized Welded Steel Bar Mesh Panel

Rebar Wire Mesh Panel for Screen Applications

Application

1. Housing and Construction

In housing construction, A252 steel mesh is used in concrete floor slabs, roof panels, and paving. As the primary load-bearing and distribution reinforcement, it effectively controls thermal and shrinkage cracks, preventing uneven settlement.

2. Road and Bridge Construction

It is used in cement concrete surfaces on highways and urban roads, and in bridge pavements. It strengthens and distributes loads, improving the impact and fatigue resistance of the pavement, thereby extending the service life of the contact surface.

3. Foundations and Public Facilities

It is used in large foundation slabs, tunnel linings, canals, reservoir structures, municipal pipeline corridors, airport runways, and port yards. The reliable steel skeleton enhances structural integrity and impermeability, meeting high demands for durability and stability.

Residential foundation construction

Bridge deck frame structure

Road reinforcement paving

British Standard Mesh Fabric Size Complies With BS 4483:2005

| Square Mesh Fabric 200mm×200mm | ||||||||

| BS REF NO. |

MESH SIZES NOMINAL PITCH OF WIRES (mm) |

WIRE DIAMETER (mm) |

CROSS-SECTIONAL AREA PER METER WIDTH (mm²/m) |

MASS (kg/m²) |

NO.0F SHEETS PER TON |

|||

| Line Wire | Cross Wire | Line Wire |

Cross Wire |

Line Wire | Cross Wire | |||

| A393 | 200 | 200 | 10 | 10 | 393 | 393 | 6.16 | 15 |

| A252 | 200 | 200 | 8 | 8 | 252 | 252 | 3.95 | 22 |

| A193 | 200 | 200 | 7 | 7 | 193 | 193 | 3.02 | 29 |

| A142 | 200 | 200 | 6 | 6 | 142 | 142 | 2.22 | 40 |

| A98 | 200 | 200 | 5 | 5 | 98 | 98 | 1.54 | 57 |

Production Process

Wire rod loading → Straightening and rust removal → Longitudinal reinforcement layout → Horizontal reinforcement layout and welding → Continuous mesh forming → Cut to length → Material collection and stacking → Inspection and packaging → Finished product storage

1. Raw Material Preparation and Pretreatment

Multiple coils of wire rod are smoothly unwound; they are straightened by straightening rollers into flat, straight wires, and then cleaned and derusted to ensure a clean weld surface.

2. Mesh Frame Construction

The straightened rebar is fed into the longitudinal conveyor system as “warp” wires. The transverse rebar is straightened, cut, and arranged on the longitudinal rebar to form the mesh frame to be welded.

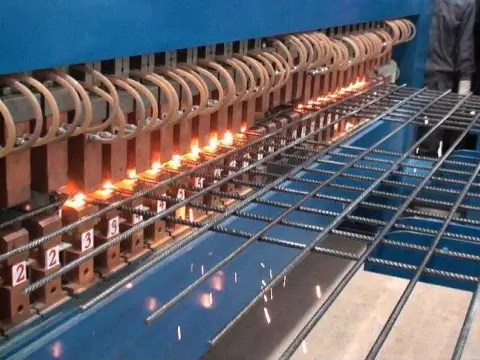

Steel rebar mesh welding production line

3. Resistance Welding

The resistance welder uses electric current and pressure to instantly melt the contact surfaces at the intersections, completing the welds at all nodes. Wanzhi Steel ensures a strong and uniform weld with no false welds or weld-throughs.

4. Cutting to Length and Stacking

The welded, infinite-length mesh is cut to the desired length by a hydraulic device. The finished mesh is then conveyed via a conveyor roller and neatly stacked by an automatic stacker.

5. Quality Inspection and Shipment

Qualification inspectors randomly check the mesh size, weld strength, and rebar specifications. If qualified, the mesh is secured with steel straps and packaged. Labels indicate the model and batch information.

Welding according to dimensions

Welded concrete mesh

FAQs

1. What does A252 mean?

A: “A” stands for standard square welded steel mesh. “252” is a model code, indicating, according to BS 4483, that the mesh has a cross-sectional area of 252 square millimeters per meter of width. The standard fixed mesh spacing is 200mm x 200mm.

2. Is the diameter of A252 steel mesh fixed?

A: No. The model “A252” only specifies the spacing and total cross-sectional area; the bar diameter must be specified separately. Commonly available diameters include 7mm and 8mm. For example, “A252 diameter 8mm” is a complete specification.

3. What is the difference between A252 and A193, and A393?

A: The main differences lie in the spacing and density of the bars:

- A193: The densest spacing (100mm x 100mm) is used in areas requiring high crack resistance.

- A252: With medium spacing (200mm x 200mm), it’s the most common type for floors and exterior walls.

- A393: With a wider spacing (200mm x 200mm), it uses thicker bars and has a higher load-bearing capacity.

4. What projects is A252 primarily used for?

A: It’s widely used, including: Residential construction: concrete floors, slabs, roofs, and walls. Road and bridge construction: cement concrete pavements and bridge decks. Public facilities: foundation slabs, small reservoirs, canals, etc.

5. Is it supplied in sheets or rolls?

A: It’s primarily supplied in standard sheets (e.g., 4800mm x 2400mm) for easier on-site handling and installation. Rolls are occasionally available.

6. How do I calculate the weight per square meter of A252?

A: The weight depends on the diameter of the bars. A simplified estimation formula is: Weight per square meter (kg/m²) ≈ Rebar diameter (mm)² × 0.00617 × 10. For example, for A252 mesh with a diameter of 7mm: 7² × 0.00617 × 10 ≈ 3.02 kg/m².

7. What information do I need to specify when purchasing A252?

A: The following information must be specified: Full model number: A252, Rebar diameter: e.g., 7mm, Sheet size: e.g., 4800mm x 2400mm, Material standard: e.g., BS 4483, Surface treatment: e.g., Plain steel, Galvanized (if required).

Factory Rebar Steel Deformed Concrete Welded Wire Mesh

Galvanized welded wire mesh shipped to Russia

A252 Reinforcement Mesh Manufacturer- Wanzhi Steel

In summary, A252 welded steel mesh is an ideal choice for improving project quality and efficiency. Wanzhi Steel, a professional manufacturer with a comprehensive production line and a 1,000-square-meter modern factory, provides comprehensive quality control from raw materials to finished products. We firmly believe that true value comes from reliable partners. We eliminate middlemen and offer highly competitive factory-direct pricing, ensuring significant cost savings. Whether you’re looking for centralized procurement for large-scale projects or long-term, stable supply, we’re ready.

Get samples or a bulk quote! Chat with Us Online,

or send an email to: info03@wanzhisteel.com

Wanzhi Steel is an ISO 9001-certified steel factory located in Hebei, China. It has been specializing in the production of Steel Reinforcement Bar, deformed steel bar, A393 Mesh, Construction Binding Wire, A142 Mesh, GI Concrete Mesh, and A193 Mesh for 14 years, with a monthly output of 1,800 tons. With high-quality products and good services, its products have been exported to more than 120 countries around the world.

Leave Us A Message

- Wire Mesh For Concrete Slab

- Expanded Metal Grating

- Diamond Mesh Lath

- Galvanized Expanded Metal Lath

- Steel Grating Plate

- Galvanised Welded Mesh Panel

- Welded Wire Fabric

- Welded Wire Sheets

- Steel Reinforcement Bar

- A193 Mesh

- Galvanized Concrete Mesh

- Steel Reinforcement Mesh

- Galvanized expanded metal mesh