Wire Rope & Cable Use Precautions

This article aims to explain the structural types, measurement methods, usage precautions, and diameter tolerances of steel cables. I hope it will be helpful to you.

WIRE ROPE IS A MACHINE. UNDERSTAND AND RESPECT IT.

Steel Cable Material Type Guide

Wire rope is a machine, like any machine, it needs proper care and maintenance for optimal safety and long service life. For a better understanding of wire rope, Wanzhi Steel highly recommends reading and understanding this article.

galvanized cable

steel rope

3 8 steel cable

Rated Capacity / Working Load Limit

Rated capacity is the load that a new wire rope may handle under given operating conditions and at an assumed design factor. A design factor of 5 is chosen most frequently for wire rope which equates to operating loads not exceeding 20% of the catalog Breaking Strength. Operating loads may have to be reduced when life, limb, or valuable property are at risk or other than when new rope is used. A design factor of 10 is usually chosen when wire rope is used to carry personnel which equates to operating loads not exceeding 10% of catalog Breaking Strength.

What types of materials are there for steel cables?

Drawn Galvanized Steel Cable

Galvanized (Zinc Coated) cable is the most popular type of steel cable. Our cable is coated using the drawn galvanizing process by

individually drawing each wire of the cable

through a molten zinc bath to completely coat

the wires. This method is superior to other

methods for corrosion resistance and finish

quality.

Galvanized cable has moderate corrosion resistance compared to stainless steel but is more ductile and resists bending fatigue more than stainless steel. Ductility and bending fatigue resistance are especially important when running over sheaves. Galvanized steel cable is stronger than stainless steel cable of the same diameter.

Type 304 Stainless Steel

Type 304 Stainless Steel cable is the desirable choice when you need a balance of strength, ductility, and corrosion resistance between 316 stainless steel and galvanized steel cable. Also known as 18-8 Stainless steel, 304 Stainless Steel cable is stronger than 316 Stainless steel cable,

but weaker than galvanized cable. It also has more corrosion resistance than galvanized steel but isn’t as resistant to corrosion as 316 stainless steel cable.

Type 316 Stainless Steel Cable

Type 316 Stainless Steel cable is the most

corrosion resistant cable of the common types available and is ideal for saltwater and chlorine environments. It also has lower strength, and bending fatigue resistance than type 304 and galvanized cable.

When using type 316 stainless steel cable with sheaves and blocks, be sure to select the largest diameter sheave suitable for the application to prevent splintering due to bending fatigue.

Vinyl Coated Steel Cable

Our vinyl-coated offerings are available in type

304 stainless steel and drawn galvanized. The

base cable retains the same properties, and the vinyl coating enhances the cable. The coating is transparent and other colors are available,

that is applied over the base cable to provide additional corrosion and abrasion resistance and give the cable a smooth finish that isn’t as rough if it comes into contact with objects, animals, or people.

Types and characteristics of steel cable structures

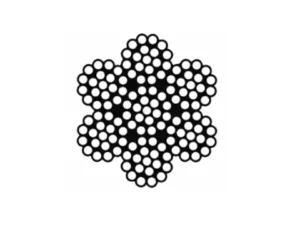

7 x 19 Construction

1. Very Flexible

2. Excellent Strength

3. Fatigue Resistant

4. Resists Crushing

Commonly used on small diameter pulleys, running rigging on sailboats, exercise equipment, winches, and control cables. 7×19 is the best all around cable for most applications.

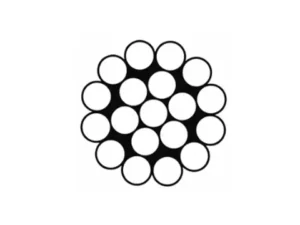

1 x 19 Construction

1. Not Flexible

2. Best for Cable Railing

3. Stronger than 7 x 19 cable

4. Good for Sailboat Rigging

5. Suitable for guying applications

6. Doesn’t kink

Commonly used on cable railings, stationary rigging on sailboats, guy wires, and push pull control cables. 1×19 is best suited for stationary applications.

7 x 7 Construction

1. Stiffer than 7×19, more flexible than 1×19

2. Stainless 7×7 commonly used for cable railings and marine applications

3. Diameters less than 1/8″ exhibit a great balance of flexibility and strength

Small diameter 7×7 cable is great for use on pulleys and general use when diameters are needed smaller than available in 7×19 construction. Coated Stainless 7×7 cable is commonly used in marine applications or cable railings, while galvanized offerings are used in general industry and agriculture.

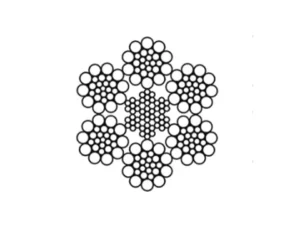

6 x 19 Construction

1. Flexible in relation to diameter

2. Excellent Strength

3. Excellent Abrasion Resistance

4. Resists Crushing

Each 6×19 wire rope strand begins with one large center wire that is covered by a layer of nine smaller wires and then an outside layer of nine larger wires. The 6×19 wire rope has larger outer wires than 7×19 which adds to an increased abrasion resistance but also decreases its fatigue resistance. This rope can stand up against abrasion or crushing on the drum.

Steel Cable Construction Explained

When a project calls for lifting or suspending a load, cable and wire rope is often the first choice because of its cost, strength, flexibility, and versatility. Compared to a solid steel rod, steel cable is nearly as strong and has the capability to bend due to its construction of many small wires.

1.) Cables of different types and structures have different properties. For example, aircraft cables and wire ropes made of many thin wires are more flexible, but small wires are more fragile and break easily.

2.) Steel cables with larger wires are more abrasion resistant but are much stiffer. The wires are twisted into strands, and the strands are twisted to form the cable.

3.) Using this method of twisting the wires and strands increases the strength, and reliability of the cable by balancing the load on all the wires.

4.) The wear resistance is also increased because the outer wires of the strands are equally exposed to wear and will wear more evenly.

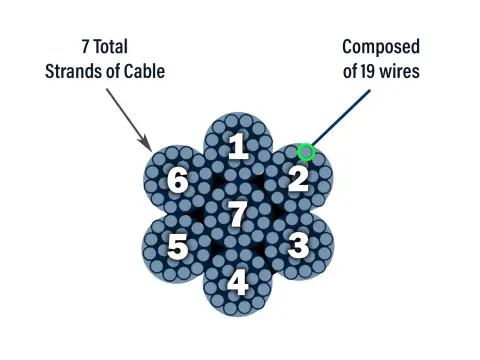

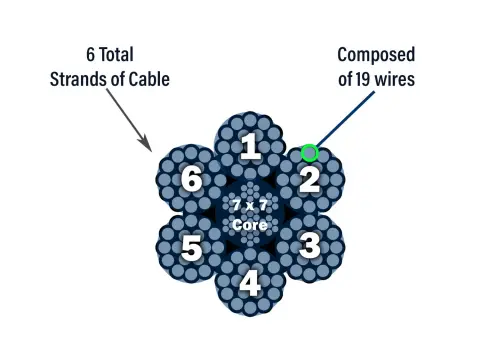

1. What does 7×19 mean?

7-x-19-cable-construction-graphic

Aircraft cable is made from 7 strands of 19 wires each. There are 6 outer strands that are preformed (bent into a helix) and one center twisted strand.

The construction of the center strand is similar to the outer strands, so it is included in the strand count.

7×19 and 7×7 cables are common for diameters 3/8” and smaller because of the simplicity of construction.

Larger diameters typically use wire rope construction methods that allow much more versatility of features to match the intended application.

2. What is 6×19 IWRC?

6-x-19-Cable-Construction-graphic

The literal meaning is 6 strands of 19 steel wires twisted together, but it looks like there are 7 strands in total. The center strand is actually a smaller diameter wire rope. IWRC stands for

“Independent Wire Rope Core”, and allows for increased flexibility, bending fatigue life, and crush resistance. ½” diameters and above typically use wire rope construction methods.

Comparison of different cable characteristics

| Cable Type | Corrosion Resistance | Flexibility | Strength | Ductility & Fatigue Resistance |

| 7 x 19 Galvanized Cable | ⭐⭐ | ⭐⭐⭐⭐⭐⭐ | ⭐⭐⭐⭐⭐⭐ | ⭐⭐⭐⭐⭐⭐ |

| 7 x 19 Vinyl Coated Galvanized Cable | ⭐⭐⭐ | ⭐⭐⭐⭐⭐ | ⭐⭐⭐⭐⭐⭐ | ⭐⭐⭐⭐⭐⭐ |

| 7 x 19 Type 304 Stainless Steel Cable | ⭐⭐⭐⭐⭐ | ⭐⭐⭐⭐⭐ | ⭐⭐⭐⭐⭐ | ⭐⭐⭐⭐⭐ |

| 7 x 19 Type 304 Vinyl Coated Stainless Steel Cable | ⭐⭐⭐⭐⭐ | ⭐⭐⭐ | ⭐⭐⭐⭐⭐ | ⭐⭐⭐⭐⭐ |

| 7 x 19 Type 316 Stainless Steel Cable | ⭐⭐⭐⭐⭐⭐ | ⭐⭐⭐ | ⭐⭐⭐ | ⭐⭐⭐ |

| 1 x 19 Type 316 Stainless Steel Cable | ⭐⭐⭐⭐⭐⭐ | ⭐ | ⭐⭐⭐⭐⭐ | ⭐⭐ |

| 7 x 7 Hot Dip Galvanized Cable | ⭐⭐ | ⭐⭐ | ⭐⭐⭐⭐⭐⭐ | ⭐⭐⭐⭐⭐⭐ |

| 6 x 19 IWRC Galvanized Wire Rope | ⭐⭐s | ⭐⭐⭐ | ⭐⭐⭐⭐⭐⭐ |

Wanzhi 5 Star Rating System Explained

You’ll see Wanzhi’s 5-Star rating system throughout our site. We rate the cable’s properties in relation to each other.

Example:

1×19 Stainless Steel cable’s flexibility is rated ⭐

7×19 Stainless Steel cable’s flexibility is rated ⭐⭐⭐

7×19 Galvanized cable’s flexibility is rated ⭐⭐⭐⭐⭐⭐

This simply means that the 1×19 stainless steel cable is the least flexible in relation to the 7×19 galvanized cable. In relation to the other two, the 7×19 Stainless Steel cable falls between the two in terms of flexibility.

Best / Most = ⭐⭐⭐⭐⭐ Worst/Least = ⭐

Matching Attachment’s Working Load Limit

The accessories that come with the wire rope must have at least the same working load limit as the wire rope.The rigging assembly can only be rated up to the weakest component minus any termination efficiencies.

Clips, sockets, thimbles, sleeves, hooks, links, shackles, sheaves, blocks, etc. must match in size, material and strength to provide adequate safety protection. Proper installation is crucial for maximum efficiency and safety.

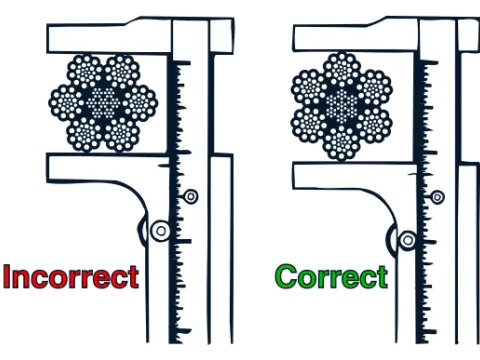

How to correctly measure the diameter of wire rope

The wire rope should be measured at the peaks of the relative strands rather than the non-relative valleys. The below figure shows the correct way to measure the cable diameter.

metal cable

Measure_Wire

airplane cable

Inspect Wire Rope Regularly

Use inspection instructions as guidelines only. Two of the most important prerequisites for inspecting wire rope are technical knowledge and experience.

Check the general condition of the wire. Also, look for localized damage and wear, especially at wire rope attachments. Inspect all parts that come in contact with the wire rope. Poor performance of wire rope can often be traced back to worn or wrong-sized sheaves, drums, rollers, etc. Look for kinks, broken wires, abrasions, lack of lubrication, rust damage, crushing, reduction of diameter, stretch, or other obvious damage. If any of these conditions exist or if there is any other apparent damage to the wire rope, retire the wire rope.

Note: When in doubt about the extent of the damage, retire the wire rope in question immediately. Without laboratory analysis, it is impossible to determine the strength of damaged or used wire. Thus, you will not be able to tell whether wire rope with any amount of damage is safe to use. Retire the wire rope that is damaged. For specific inspection procedures check various OSHA, WRTB, ANSI, and ASTM publications.

Wire Rope Diameter Tolerances

| Wire Rope Diameter (in) | Tolerance (in) | |

| Under | Over | |

| 1/32 | 0 | 0.006 |

| 3/64 | 0 | 0.008 |

| 1/16 | 0 | 0.010 |

| 3/32 | 0 | 0.012 |

| 1/8 | 0 | 0.014 |

| 5/32 | 0 | 0.016 |

| 3/16 | 0 | 0.018 |

| 7/32 | 0 | 0.018 |

| 1/4 | 0 | 0.018 |

| 9/32 | 0 | 0.020 |

| 5/16 | 0 | 0.022 |

| 3/8 | 0 | 0.026 |

Get Wire Rope & Cable Price – Wanzhi Steel

Wanzhi Steel specializes in the production of cables and wire ropes of various materials. Our experts are always waiting to solve your problems. We accept customized solutions, free sample services, and a large number of standard export packaging in stock. Our products have been sold to more than 150 countries around the world. If you are interested, please feel free to contact us~

WhatsApp: 8613938459717(Click to Directly Chat)

Email: info03@wanzhisteel.com(Click to Email)

Leave Us A Message