Why Choose Annealed Wire?

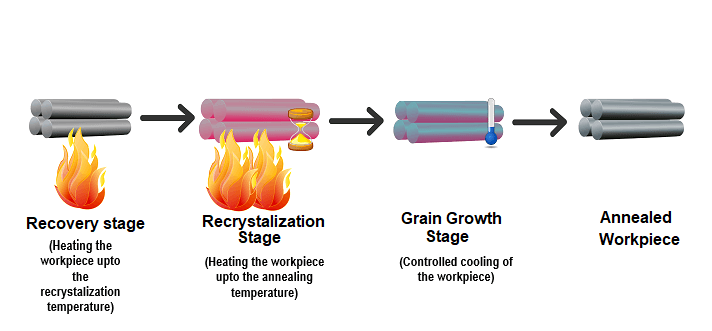

Black annealed wire, also known as black high-temperature wire, is a black iron wire drawn from a Q195 wire rod, or a filamentary material made of high-temperature materials such as metal molybdenum and tungsten. The figure below records the main steps of wire annealing. Annealing is aimed at improving various properties of wire, including strength, stability, corrosion resistance, and life.

Annealing-process

Its name comes from its surface color – black, its surface oxide layer caused this. Choosing black annealed is primarily based on its unique physical and mechanical characteristics, as well as its suitability for different applications.

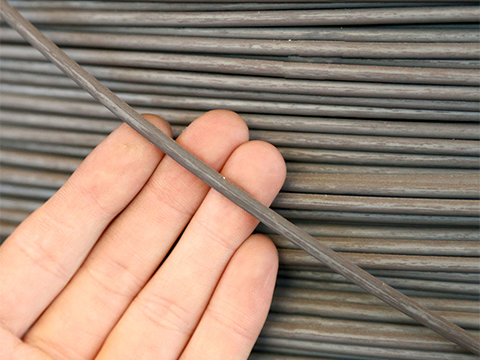

It looks like ordinary black iron wire, but its performance is far superior to ordinary black iron wire. Here are the main reasons why choose black annealed steel wire.

1. It is easier to bend, stretch, and shape

The steel wire is cooled slowly after reaching a specific temperature. This process, called annealing (or softening), produces wire with excellent plasticity and strength.

This treatment improves the plasticity and strength of steel wire by reducing its hardness.

The annealed steel wire is therefore easier to bend, stretch, and shape. This makes it more advantageous in situations that require bending and twisting.

annealed-stainless-steel-wire

Black Annealed Twisted Wire

Annealed Wire Binding Surface

2. It is more stable and less likely to break

Reduced stress concentration: Annealing eliminates the residual stresses and internal defects where the steel is during production and can reduce stress concentration. Due to stress concentration, the annealed steel wire is more stable and less likely to break or fail.

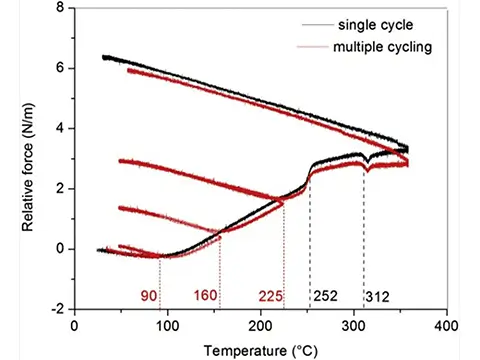

3. It is more corrosion and fatigue-resistant

Annealing can improve wire corrosion resistance and durability. Although annealing does not directly increase the corrosion resistance of steel wires, it can enhance their corrosion resistance by optimizing their organizational structure and chemical makeup.

The annealed steel wire is also more durable and has a higher fatigue resistance. This makes it suitable for long-term applications.

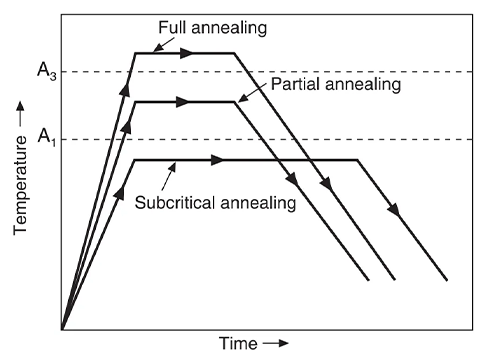

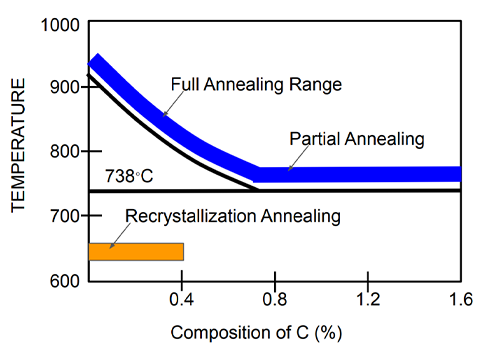

Annealing time temperature diagram

Relative-force-of-single-and-multi-strand

C content and temperature during annealing

4. It has a longer service life

The annealing process makes it have excellent wear resistance and ductility, able to withstand greater tension, and a dense oxide film will be formed on its surface, which can also resist the invasion of acid and alkali materials, thereby reducing the occurrence of rust. Therefore, its service life is longer than that of ordinary iron wire, reducing the frequency of replacement and reducing costs.

5. It is high cost-effectiveness

Although the production costs of annealed steel are slightly higher than those of untreated wire, their excellent performance and broad range of applications make them highly cost-effective. Production costs can be minimized by selecting the right annealing materials and processes.

6. Its wider range of uses than ordinary steel wire

It has a wide range of uses: It is used in many industries including construction, automotive, electronics, and aerospace. For example, it is used to create scaffolding and steel mesh. In the machinery industry, it is used to manufacture springs, fasteners, and other components. While in the electronics industry, annealed cables can be used for wires and cables.

Furniture, spring

Lampshade, decoration

7. Its beautiful surface

The surface of it is very bright, with no uneven color, complete coating, and high aesthetics. For some occasions with higher requirements, such as high temperature and humidity, craft decoration, black annealed wire can fully meet the requirements, while ordinary steel wire has a poor effect.

WANZHI Black Annealed Wire Case

Loading Annealed Wire to Truck

Wanzhi Steel—Annealed Wire Supplier in China

In summary, black annealed wire has become an ideal choice in many industries due to its excellent wear resistance, tensile strength, easy processing, corrosion resistance, flexibility, surface beauty, and long service life, as well as its affordability. Because annealing changes the physical and chemical properties of the wire, In practical applications, choosing the right annealed-wire materials is important based on specific needs.

Black annealed wire is available in a variety of brands and specifications in the market, and prices vary depending on the brand, specification, and supplier.

Black Annealed Wire to Turkey

Black Annealed Cutting Wire

Annealed spring wire in coil for nails making

Wanzhi Steel is a professional annealed wire steel mill with an annual export volume of 300,000 tons. We have dozens of cooperative customers all over the world.

We use Q195, Q235 as the raw material, and each roll weighs 10-800 kg ( According to customer requirements ). The packaging is In coils or spools. Plastic film inside and woven bag outside.

Get samples or a bulk quote! Chat with Us Online,

or send an email to: info03@wanzhisteel.com

Wanzhi Steel is an ISO 9001-certified steel factory located in Hebei, China. It has been specializing in the production of Gi wire, Aluminium Wire, low carbon wire, Spring wire, Black Annealed Wire, Baling Wire, SS wire, Stitching wire, and galfan coated wire for 14 years, with a monthly output of 1,800 tons. With high-quality products and good services, its products have been exported to more than 120 countries around the world.

Leave Us A Message