Steel Grating Plate

Steel grating plate is made of flat bars and cross bars welded at a certain spacing. These kinds of steel products are often used as gutter covers, platform plates, step plates of steel ladders, and so on. This product has strong pressure resistance, convenient transportation, and can prevent oxidation after galvanizing. Wanzhi Steel is a high-quality manufacturer of metal grating sheets, making steel grating sheets of various shapes, with carbon steel, stainless steel, and aluminum options, hot-dip galvanizing, painting, and powder coating options, and accepts customization of width, thickness, length, and spacing. If you are interested, you are welcome to contact us at any time.

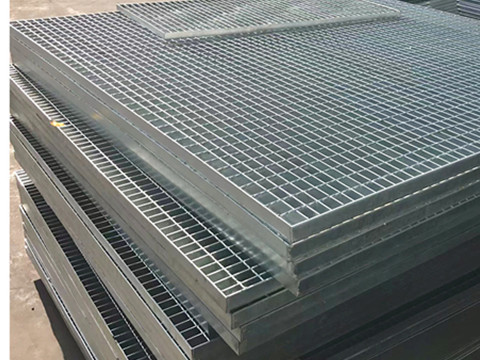

Steel Grating Plates

Sidewalk Driveway Floor Grating

Specification

| Item | Steel Grating Plate |

| Place of Origin | Hebei, China |

| Standard | AISI, ASTM, DIN, JIS, GB, EN |

| Weld Way | Welded, Pressure-locked, Swage Locked |

| Color | Silver |

| Type | Serrated, Plain, I bar grating |

| Flat Steel Shape | Flat Bar, Serrated Bar, I-Bar, Inserting Steel Grating, etc. |

| Shape | Square, round, rectangle |

| Flat Steel Thickness | 2.5 mm – 12 mm |

| Flat Steel Width | 20 mm – 150 mm |

| Flat Steel Spacing | 20 mm – 100 mm |

| Crossbar Spacing | 50/100 mm |

| Sample | Free Available |

| Payment term | TT 30% Advance + 70% Balance |

| Price Item | FOB, CIF, EXW, CFR, etc |

| Packing | Standard export packaging |

| Certification | ISO 9001, SGS, ABS, BV |

| MOQ | 5 tons |

| Transportation | By land, by sea |

| Usage | Ditch Cover, Platform, Walkway, Ladder Treads, etc |

I-shaped Grating

Toothed Steel Grating

Features of Steel Grating Plate

- High strength and light weight: carbon steel or SS steel is used, and the flat steel and the crossbar are welded/pressed into a grid structure, with uniform load distribution, suitable for heavy industrial scenes.

- Strong corrosion resistance: carbon steel hot-dip galvanized (zinc layer 60-100μm), with a service life of more than 10 years; stainless steel is naturally rust-proof and acid-resistant, suitable for chemical and marine environments.

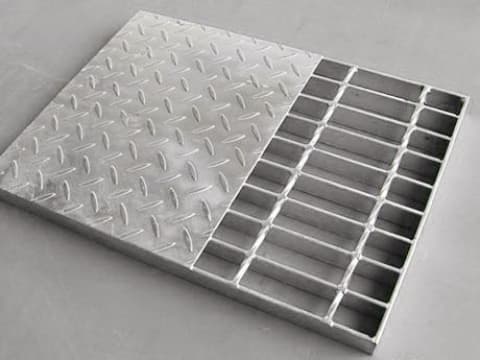

- Safe and non-slip: toothed flat steel or embossed surface design improves friction, suitable for slippery areas such as stairs and wet platforms.

- Ventilation and lighting: The grid structure has a ventilation rate of 30%-80%, fast heat dissipation, good light transmittance, saving lighting energy consumption, suitable for power plants, parking lots, etc.

- Easy maintenance: open grids drain quickly, no dirt accumulation, can be cleaned by rainwater, self-cleaning ability, wear and scratch resistance.

- Convenient installation: modular design, support hinge/bolt connection, 2 people can lay 80㎡ in 1 day, no complicated welding required.

checker plate grating

Galvanized Steel Bar Grating

- Flexible customization: adjustable flat steel spacing, crossbar type, support for special-shaped cutting and edging, and adaptable to complex needs.

- Beautiful and durable: neat grid shape, silver-bright zinc coating or polished treatment, both functional and decorative. The cost is lower than brick wall/wood, economical, and efficient.

Export Case

steel grating shipped to Yemen

Applications of Steel Grating Plate

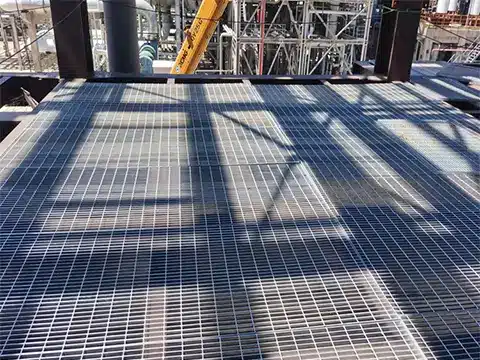

- Industrial field: factory operation platform, petrochemical storage tank platform, power aerial work platform, supports heavy load, and adapts to a special environment.

- Construction and municipal administration: stair treads (anti-slip and light-transmitting), drainage ditch cover (lightweight and corrosion-resistant), bridge maintenance channel/landscape plank road.

- Transportation: port loading and unloading platform, underground garage ventilation floor, railway platform, and track maintenance channel.

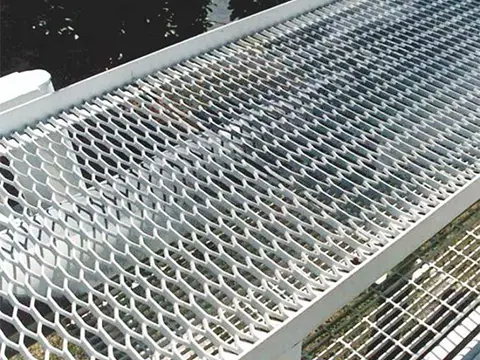

- Environmental sewage: sewage treatment plant filter grille, landfill leachate ditch cover, ventilation system protection net.

- Marine anti-corrosion: offshore drilling platform, ship deck, coastal terminal facilities, resistant to seawater salt spray erosion.

- Agricultural breeding: poultry and livestock house ventilation floor, feed factory conveying platform, to ensure hygiene and operational safety.

- Safety decoration: factory safety fence (anti-fall), park decorative guardrail/paving (combined with lighting design).

Steel Grating for Construction Site

Stair Treads

galvanized walkway grating

How to Choose the Right Steel Grating Plate?

1. Formed by flat steel 65 mm – 200 mm wide and 5 mm – 20 mm thick welded steel grating: suitable for large parking lots, dock sites, road and bridge warehouse construction, etc. with strong load-bearing capacity.

2. Steel grating with 40 mm spacing: This kind of steel grating has the highest cost performance. It is one of the ideal choices for small-span occasions.

3. Grating with 60 mm flat bar spacing and 50 mm cross bars: commonly used in mining processing sites to prevent ore residue from splashing.

4. Steel grating with 30 mm flat bar spacing: This type of grating is the most widely used in the industrial field.

Round galvanized grating sheet

galvanized metal grating

expanded metal catwalk grating

How to Make Steel Grating?

1. Material preparation: cutting load-bearing flat steel (carbon steel/stainless steel, flat/toothed) and crossbars (round steel, square steel, or twisted square steel).

2. Welding/press-locking forming: the flat steel is arranged according to the spacing, and the crossbar is vertically inserted and fixed by welding or press-locking.

3. Surface treatment: pickling, sandblasting, and rust removal, followed by hot-dip galvanizing, painting, or stainless steel polishing and other anti-corrosion treatments.

4. Cutting inspection: cutting according to size, checking the appearance, size, and quality before leaving the factory.

Stainless steel grille welding

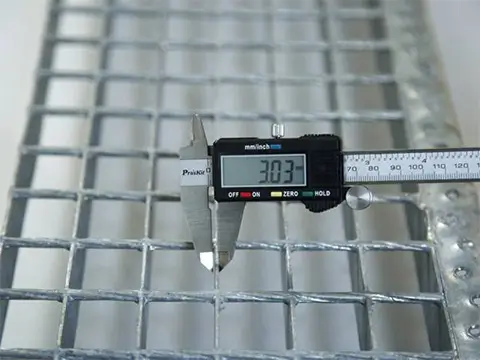

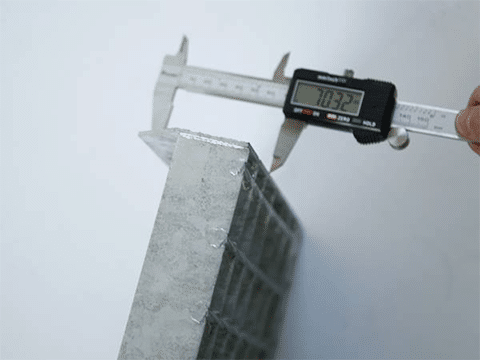

Thickness test of steel grating sheet

Thickness test of steel grating plate

Service life of steel grating in different environments

| Environment type | Hot dip galvanized steel grating | Stainless steel grille | Other materials |

| Ordinary dry environment | 25-30 years | 304 stainless steel: 40+ years | Bare steel: 3-5 years (maintenance required) |

| Wet/high humidity | 15-20 years | 316 stainless steel: 30+ years | Galvanized + sprayed: 20-25 years |

| Industrial corrosive environment | 10-15 years | 316L stainless steel: 20-25 years | PVC edging: 8-12 years |

| Marine environment | 8-12 years | 2205 duplex steel: 25+ years | Aluminum grille: 15-20 years |

| High temperature environment | 5-8 years | 310S stainless steel: 15-20 years | Heat-resistant steel: 10-15 years |

| Extreme cold environment | 20-25 years | Stainless steel: 30+ years | Low-temperature steel: 25 years+ |

Key influencing factors

- Zinc layer thickness: Every 20μm increase in life extends the service life by 3-5 years.

- Use environment: 316L or duplex stainless steel is required in marine environments due to high chloride ion concentration.

- Mechanical wear: Thickened flat steel (such as 40mm or more) is required in high traffic areas.

- Maintenance frequency: Regular cleaning can extend the service life by 20%.

galvanised grating

Grooved grating drain cover

Pre-purchase tips

Therefore, before purchasing you have to comprehensively evaluate the environment of your project and consider factors such as air humidity and ambient humidity. When communicating with the manufacturer, you should explain the anti-corrosion design requirements of the steel grating and determine the material of the coating.

In this way, we can customize the steel grating for you according to your specific requirements.

Steel Grating For Sale-Wanzhi Steel

As a professional steel grating manufacturer, Wanzhi Steel provides customers with high-strength, corrosion-resistant and long-life high-quality steel grating products with advanced production technology, and rich industry experience. Whether you need an industrial platform, drainage cover, anti-slip step, or marine engineering grating, Wanzhi Steel can provide cost-effective, safe and reliable solutions. Contact us for professional selection advice and quotes!

About Wanzhi Steel

- Advanced production line: fully automatic welding and hot-dip galvanizing process to ensure product precision and durability.

- Strict quality inspection: In compliance with ISO 9001, ASTM international standards, each batch of products is strictly tested.

- Customized service: supports different materials, specifications, and surface treatment solutions(19w4 grating, 11w4 grating, and 15w4 grating, steel trench drain or sink bottom grid).

- Fast delivery: products are exported worldwide, covering an area of 1000+ square meters for large inventory, and delivery within 8-18 days.

or send an email to:info03@wanzhisteel.com

Wanzhi Steel is an ISO 9001-certified steel factory located in Hebei, China. It has been specializing in the production of Diamond Mesh Lath, Galvanized expanded metal lath, Galvanized Concrete Mesh, Expanded Metal Grating, and Galvanized Grating for 14 years, with a monthly output of 1,800 tons. With high-quality products and good services, its products have been exported to more than 120 countries around the world.

Leave Us A Message