Perforated Aluminum Sheets

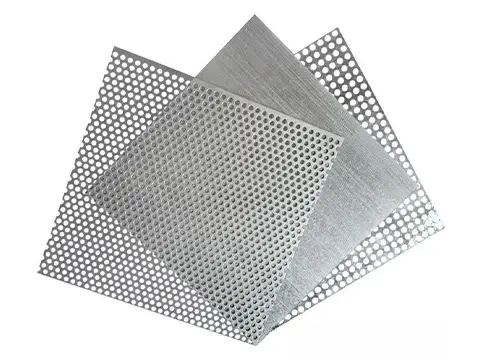

Perforated aluminum sheets are aluminum sheets made by mechanical pressure processing, which feature evenly spaced holes formed into the aluminum sheet. Perforated aluminum mesh is highly resistant to corrosion, is a relatively light metal compared to metals such as steel, nickel, brass, and copper, and is fairly ductile. Aluminum sheets with holes can have a variety of surface finishes and are highly reflective of heat and light. As a high-quality aluminum plate supplier, Wanzhi Steel stocks a large number of conventional perforated aluminum plates and accepts customization of plate thickness, hole spacing, and hole type. If you want to learn more, please contact us.

Wanzhi Steel provides all size options and hole type options.

You can send your requirements to online technicians.

micro perforated aluminum sheet

perforated aluminum sheet 4×8

Perforated aluminum sheet 4×8

Specification

| Item | Perforated aluminum seetsh |

| Place of Origin | Hebei, China |

| Delivery Time | 8-14 days |

| Standard | AISI, ASTM, DIN, JIS, GB, EN |

| Technique | Punching |

| Material Grade | 1050, 1080A, 1100, 1199, 2036, 3003, 5052, 5056, 5083, 5456, 6060, 6061, 6063, 7075 |

| Special Material Options | 304/304L/316/316L Stainless steel, Galvanized steel, Alu zinc coated steel |

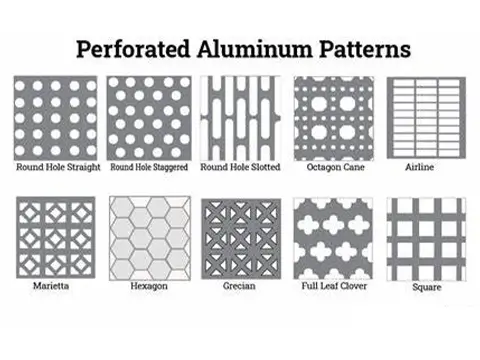

| Opening Shape | Round, square, rectangular, diamond, pentagon, raised round, custom shape |

| Thickness | 0.5mm-3.0mm |

| Width | 10-1500mm |

| Length | Customizable |

| Sample | Free Available |

| Payment term | TT 30% Advance + 70% Balance |

| Price Item | FOB, CIF, EXW, CFR, etc |

| Packing | Standard export packaging |

| Certification | ISO 9001, SGS, ABS, BV |

| MOQ | 5 tons |

| Function | Screening/separation/sorting/sieving/Grading/Filter |

| Transportation | By land, by sea |

What is Aluminum Perforated Metal?

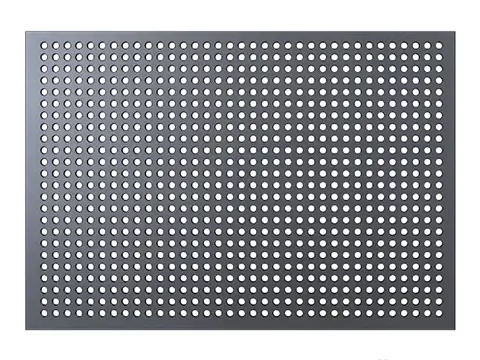

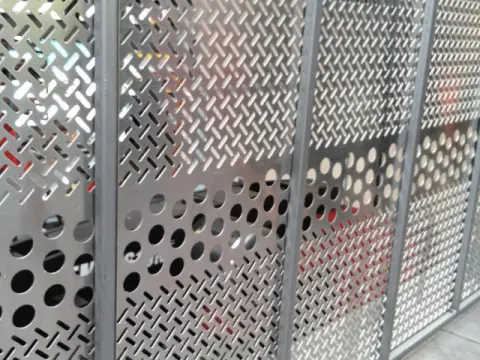

Perforated aluminum sheet metal is a sheet of metal that has been punched or embossed with a pattern of holes or other shapes. The perforations come in a variety of shapes and sizes for beauty and strength. They are commonly used in building exteriors and industrial applications such as ventilation systems, noise reduction systems, and filtration and screening applications. Aluminium hole punching sheets are favored for their lightweight, corrosion resistance, formability, and air and light permeability.

Perforated aluminum panels

perforated aluminium mesh

aluminium perforated screen

For most applications, they do not require a protective coating and are usually anodized to improve color and strength. Punched aluminum sheets are very useful at low temperatures. At temperatures below zero, they increase in strength while maintaining ductility, and at temperatures above 400°F, aluminum sheets lose some of their strength.

Features

1. Lightweight: This is its significant advantage. Aluminum has a lower density than steel, is lightweight, and is easy to transport and install.

2. Corrosion resistance: The natural oxide layer is rust-proof and weather-resistant, suitable for humid, outdoor or industrial environments.

3. High air permeability: Various hole types, including round holes, square holes, hexagonal holes, etc., taking into account ventilation, heat dissipation and filtration functions.

4. Moderate strength: It can be treated with alloys such as 5052 and 6061 to improve rigidity and meet structural requirements.

5. Beautiful and customizable: The surface can be anodized, sprayed, or polished, and the hole type, hole diameter, arrangement and color can be designed according to requirements.

6. Easy to process: It supports cutting, bending, welding, and is suitable for multiple uses such as architectural decoration and mechanical protection.

black perforated aluminum sheet

Modeling perforated galvanized sheet, MS sheet

Indoor basketball court fence

Application Areas

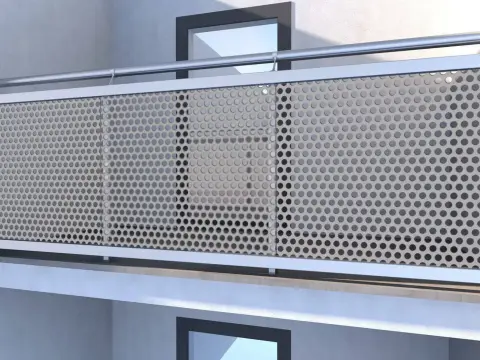

1. Curtain wall and facade: for decoration, controlling light transmission, sound absorption, ventilation and energy reduction functions, dynamic light and shadow, and anti-glare.

2. Ceiling and partition: used in public buildings and homes such as cinemas, studios, multimedia rooms, etc., to improve sound quality conditions, or noise reduction facilities in workshops, factories, and basements.

3. Filtration and separation: used in filters for chemical, food, pharmaceutical, and other industries, for gas or liquid separation.

4. Mechanical protection: made into protective covers or fences, divides safe storage areas, and improves safety and management efficiency.

5. Home & Commercial: kitchen supplies, high temperature resistant utensils, etc., artistic modeling, improve levels and grades.

6. Ventilation and heat dissipation: heat dissipation holes of computer hosts, grain dryer nets, window machine nets, and air outlets of home appliances. Ventilation and air exchange are parts of automobiles.

Perforated Sheet Aluminum Stainless Steel

round hole aluminum perforated sheet

Art Deco Covering Panels

Common Grades

1100 (pure aluminum)

Industrial pure aluminum, excellent corrosion resistance and processability, but low strength, suitable for decorative purposes that require lightweight and weather resistance, such as signs, lampshades, etc.

3003 (aluminum-manganese alloy)

Adding manganese elements to pure aluminum improves strength and corrosion resistance, high cost performance, and is widely used in building curtain walls, kitchenware, and general sheet metal parts.

5052 (aluminum-magnesium alloy)

High magnesium content, excellent seawater corrosion resistance, and medium-to-high strength, commonly used in ships, vehicle parts, and outdoor structural parts.

6061 (aluminum-magnesium-silicon alloy)

High strength, heat-treatable strengthening, balanced weldability, and mechanical properties, one of the preferred materials in the fields of aerospace and machinery manufacturing.

6063 (extruded alloy)

Specially optimized for the extrusion process, excellent formability and surface treatment performance, mainly used for building profiles such as door and window frames and railings.

Building cladding

custom perforated aluminum sheet

Interior decoration

Physical & chemical properties of 3003 aluminum alloy

Physical properties

| Property | Value |

| Density g/cm^3 | 3 |

| Ultimate Tensile Strength KSI | 22 |

| Brinell Hardness 500 kg load | 40 |

| Yield Tensile Strength KSI | 21 |

| Elongation % in 2 in. | 8 |

| Shear Strength KSI | 14 |

| Melting Point °F | 1190 – 1210 |

| Machinability % | 30 |

| Electrical Conductivity % IACS | 44 |

Chemical properties

| Chemistry Information: 3003 Aluminum | |

| Element | Percentage |

| Al | 98.7 |

| Cu | 0.05 – 0.2 |

| Fe | 0.7 max |

| Mn | 1 – 1.5 |

| Si | 0.6 max |

| Zn | 0.1 max |

perforated corrugated aluminum panels

oval perforated aluminum sheet

Park and road fences

What is its production process?

Aluminium perforated is produced by a punching or perforation process. The process includes the following steps:

1. Raw material preparation

Aluminium sheets are prepared according to the required size and thickness.

2. Punching and forming

The required hole pattern is created in the aluminium sheet using a punching machine, and then the aluminium sheet is bent or sheared into the required shape. The punching process can be carried out using a variety of techniques, including mechanical punching, laser cutting, and water jet cutting.

3. Surface treatment

The perforated metal aluminium sheet can be subjected to surface treatments such as anodizing, powder coating, or painting to enhance its aesthetics and corrosion resistance.

5052 aluminum plate 5754 aluminum plate

Laser perforation

perforated aluminum screen

FAQs

1. Which shape is the most popular?

The most common aluminum perforated metal sheet mesh shape is a round hole pattern. Because round holes provide a good balance between open area and strength, round-hole aluminum perforated screen can be used for filtration, ventilation, decorative purposes, etc. Our best-selling option has a 3 mm round hole.

2. How strong is aluminum perforated metal?

The actual strength of perforated aluminum mesh depends on many factors, such as plate thickness, hole diameter, hole spacing, etc. Since it is lighter than Galvanized perforated sheets, MS perforated sheets, and SS perforated sheets, its strength is not as good as these materials, making it have a good strength-to-weight ratio and suitable for applications where both strength and weight are critical.

slotted aluminum metal sheet

Safety fence

hexagonal perforated aluminum sheet

3. How to increase the strength of aluminum perforated mesh?

The strength of aluminum perforated metal screen sheet can be further improved by choosing a thicker sheet or a smaller hole pattern. The design of the screen must take into account the specific application and any load or stress requirements that may exist. In contrast, a stainless perforated sheet is stronger and may be suitable for your needs.

4. Can Perforated aluminum sheets be bent?

Like aluminum sheets, it is completely bendable. The degree of bend depends on the thickness and hole shape of the aluminum sheet. This step can be done with the help of a bending machine. A bending machine is a tool used to bend aluminum sheets to the desired angle.

5. Can I spray paint Perforated aluminum sheets?

Yes, Perforated aluminum sheets can be painted. Same painting steps as perforated galvanized sheets. The basic process is as follows: Clean dirt and grease → Dry → Choose a paint that is compatible with aluminum and its use → Apply with a spray gun, brush, or roller → Dry → Quality check → Moisture-proof storage → Regular maintenance → Timely repair.

decorative perforated metal panels

Color coated roof panels

Export Packaging

6. Can Perforated aluminum sheets be welded?

Yes, but it requires certain skills. Aluminum alloy has a low melting point and high thermal conductivity, and the welding process can easily cause the plate to deform or melt. Perforated aluminium mesh is commonly used in tungsten inert gas (TIG) welding, which can accurately control the heat input and produce high-quality welds while reducing deformation.

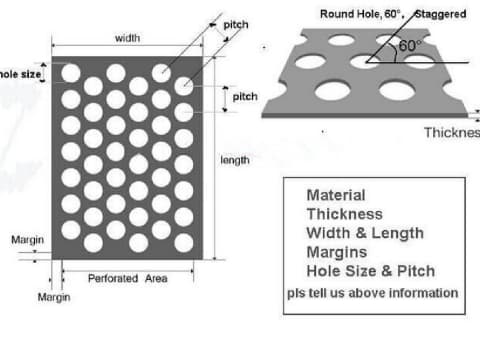

How do I calculate the spacing of perforated metal?

The pitch of a perforated aluminium mesh is the distance between the centers of adjacent holes in the metal sheet, also known as center-to-center spacing.

To calculate its pitch, follow these steps:

1. Measure the diameter of the hole: this is the distance at the widest point of the hole.

2. Select two adjacent holes: these are the holes closest to each other and share a common border.

3. Measure the distance between the centers of

The two holes: this is the pitch or center-to-center distance.

4. If you have a rectangular or slotted pattern, measure the length and width of the openings rather than the diameter of the holes.

5. The pitch can be expressed in units such as millimeters or inches, depending on the measurement system you use.

6. Repeat the process for multiple holes in different areas of the mesh or perforated aluminium strip to ensure accuracy.

Dimensional measurement parameters

Perforated aluminium sheet price

The unit price is not fixed. The factors that affect the price are mainly the following three points:

1. Alloy composition

The higher the precious metal content in the aluminum perforated panel, the higher the price is usually.

2. Thickness

The thicker the aluminum plate, the higher the price.

3. Hole pattern

The more complex the holes, the more difficult it is to process, and the price will increase accordingly.

Perforation Pattern

corrugated perforated aluminium sheet

perforated aluminium sheet suppliers package

Aluminum Perforated Sheets Supplier – Wanzhi Steel

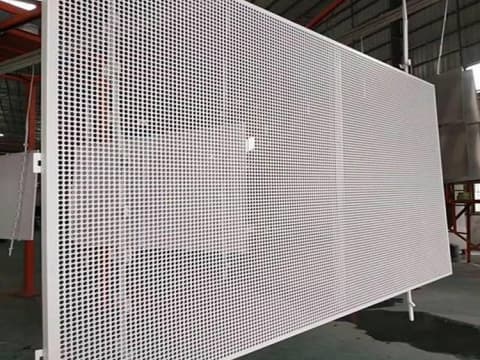

Wanzhi Steel can create dynamic and smooth images on perforated aluminum panels, providing standard straight line designs and staggered designs to meet your unique needs. Whether it is building curtain wall, mechanical filtration or decoration engineering, Wanzhi Steel can provide you with a one-stop solution of professional advice + high-quality products + reliable services.

About Wanzhi Steel

✅ Advanced intelligent manufacturing: fully automatic CNC equipment ensures precision punching and accurate and consistent hole shape

✅ Strict quality control: ISO certified production system, each batch of products undergoes strict testing

✅ Professional customization: supports personalized hole shape, size and surface treatment solutions

✅ Fast delivery: 10,000 tons of raw material inventory, efficient response to various order requirements

Consult our technical team now to get exclusive perforated aluminum plate solutions!

or send an email to: info03@wanzhisteel.com

Wanzhi Steel is an ISO 9001-certified steel factory located in Hebei, China. It has been specializing in the production of SS steel wire mesh, Galvanized Diamond Mesh, Galvanized Steel Wire Mesh, GI expanded metal mesh, Crimped Wire Mesh, Insect screens, Gabion Basket, and Poultry Netting for 14 years, with a monthly output of 1,800 tons. With high-quality products and good services, its products have been exported to more than 120 countries around the world.

Leave Us A Message