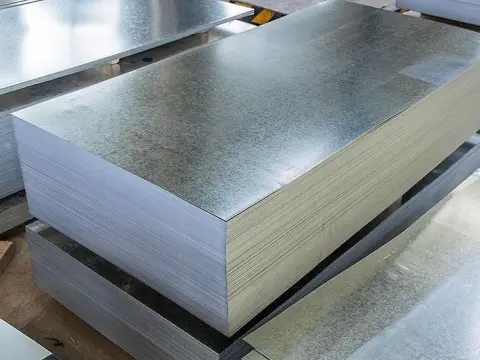

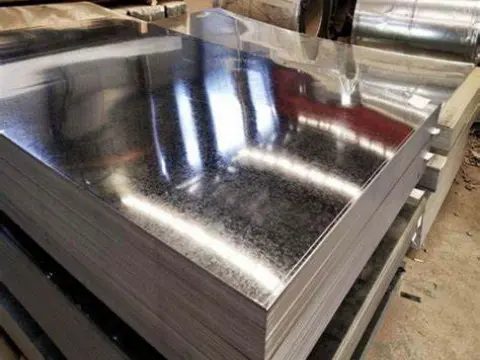

Galvanized Steel Sheet

Galvanized Steel Sheet/Galvanized Carbon Steel Sheet/Thick Sheet is an important metal material with a hot-dipped galvanized surface to prevent corrosion. This steel sheet has excellent weather resistance, corrosion resistance, and durability and is widely used in construction, home appliances, automobiles, and other fields. Features such as high flatness, high strength, and easy processing make it very popular in the market. Wanzhi Steel is oriented to meet customers’ needs, support various customized solutions, and take product quality as our purpose, welcome to consult.

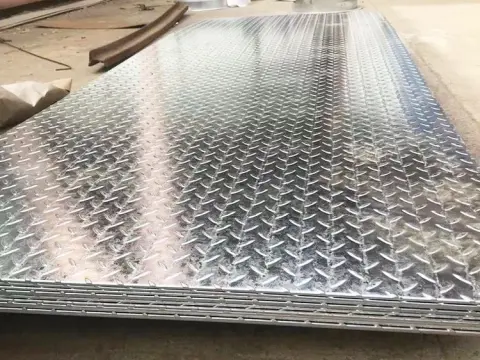

gi Carbon Steel Checker Plate Sheet

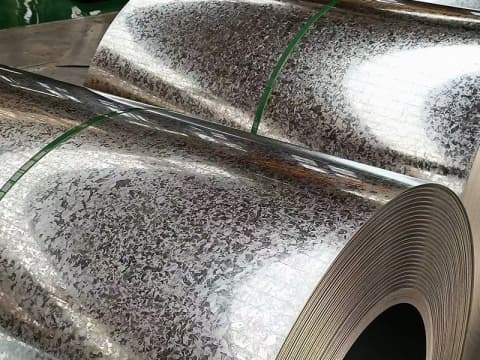

Spangle Galvanized Roofing Gi Sheets

Specification

| Item | Galvanized Steel Sheet |

| Place of Origin | Shandong, China |

| Standard | AISI, ASTM, DIN, JIS, GB, EN |

| Technique | Hot Rolled Cold Rolled |

| Processing Service | Welding, Punching, Cutting, Bending, Slitting |

| Surface Treatment | Passivation(C), Oiling(O), Lacquer sealing(L), Phosphating(P), Untreated(U) |

| Surface Structure | Big Spangle, regular spangle, small spangle, mini spangle |

| Shape | Flat sheet, profiled sheet, corrugated sheet, perforated sheet |

| Length: | 1-12m |

| Width | 10-1500mm |

| Sample | Free Available |

| Payment term | TT 30% Advance + 70% Balance |

| Price Item | FOB, CIF, EXW, CFR, etc |

| Packing | Standard export packaging |

| Certification | ISO 9001, SGS, ABS, CE, BV |

| MOQ | 5 tons |

What is galvanized sheet steel?

Galvanized steel is made from ordinary steel sheets with a galvanized surface to improve its corrosion resistance and extend its service life. Continuous hot dip galvanizing is generally used so that rust rarely appears on the surface of the steel sheet over time. Galvanizing is a widely used rust prevention measure. After galvanizing, zinc grains, or “zinc spangles”, appear on the surface of the steel, the size of which can be controlled. Grains smaller than 0.2mm are small zinc flowers, and grains 0.2mm and larger are large zinc flowers.

Production Video

This is one of our production lines and packaging and delivery video.

Properties

- Excellent corrosion resistance: the zinc layer effectively isolates air and moisture, thus avoiding oxidation and rust.

- Long service life: much longer than ordinary steel sheets, 20-50 years or more in normal environments.

- Low maintenance requirement: virtually maintenance-free and therefore economical, can be used without painting.

- High strength, light weight: Inheriting the high strength characteristics of steel, galvanized treatment is lighter than traditional materials.

- Easy processing: good plasticity and processability, suitable for cutting, welding, bending, and stamping.

- Resistance to abrasion: high surface hardness, adaptable to mechanical abrasion and impact.

- Wide application: in addition to construction, it also has applications in the automobile and home appliances, industry, and agriculture.

Hot rolled DX51D G90 galvanized sheet

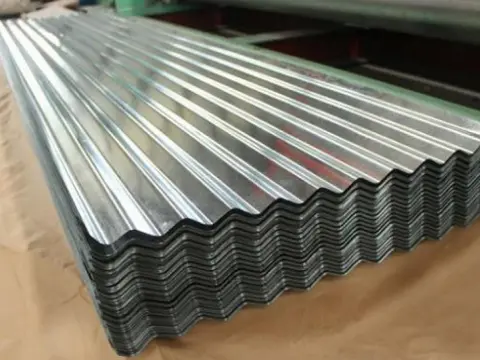

Galvanized Corrugated Roof Panels

Weight calculation formula

Weight (kg) = Thickness (mm) × Width (m) × Length (m) × 7.85

The density of galvanized steel sheet is usually 7.85g/cm³ (or 7850kg/m³).

Coating thickness formula

The coating thickness formula is: Dz = coating weight per square meter g (coating area mm2*zinc specific gravity).

The formula can be simplified to: Dz = 0.000139Gz.

Gz: coating weight per square meter g.

Two types of galvanizing method

According to the production and processing methods, it can be divided into the following categories:

Hot-dip galvanizing

Said as HDG, the steel coil passes through a high-temperature molten 99.5% pure zinc bath, usually hot-dip galvanizing continuously. In industry terminology, HDG is also called GI.

Electro galvanizing

The coating is thinner and the corrosion resistance is not as good as the hot-dip method; zinc is applied by electroplating instead of zinc dipping, zinc is used as the anode and steel is used as the cathode, and the surface effect is good. It is called “EG” in industry terminology.

Surface Structure- Big, Regular, Small, Zero Spangle

Coating weight comparison table

Code meaning

“Z” means hot-dip galvanized, and the number represents the total weight of double-sided coating (g/m²).

| Code | Total weight on both sides (g/m²) | Single-sided coating thickness (μm) | Service life |

| Z60 | 60 | ~4.2μm | 5-15 years |

| Z90 | 90 | ~6.3μm | 5-15 years |

| Z100 | 100 | ~7.0μm | 5-15 years |

| Z120 | 120 | ~8.4μm | 5-15 years |

| Z150 | 150 | ~10.5μm | 15-30 years |

| Z200 | 200 | ~14.0μm | 15-30 years |

| Z275 | 275 | ~19.3μm | 15-30 years |

Uses of galvanized steel sheets

Construction

Use Z120-Z200, ASTM A653, JIS G3302 grades with good corrosion resistance and molding properties for roofs, structures, and walls.

Appliances

Z100-Z150, ASTM A653, JIS G3302 grade galvanized steel sheet with smooth surface, suitable for stamping and forming. Used for appliance housings and internal structures

Automotive

Z150-Z275, ASTM A792, JIS G3313 grade galvanized steel, high strength, and high corrosion resistance, suitable for automotive body and structural parts.

Industrial

Z200-Z275, ASTM A875, EN 10147, high strength and corrosion resistance, suitable for industrial equipment and structural parts.

house elevation

corrugated-metal-wall-entryway

Elevator Riser

The Uses of Different Standard Systems

1. ASTM Standard (American Society for Testing and Materials)

| Grade | Characteristics | Uses |

| ASTM A653 | Ordinary galvanized steel sheet with good formability and weldability | Construction, home appliances, automotive parts |

| ASTM A792 | High-strength galvanized steel sheets for applications requiring high mechanical properties | Structural components, industrial equipment |

| ASTM A875 | Weather-resistant galvanized steel sheets for highly corrosive environments | Outdoor construction, bridges, guardrails |

2. JIS standard (Japanese Industrial Standard)

| Grade | Characteristics | Uses |

| JIS G3302 | Ordinary galvanized steel sheet with good corrosion resistance and formability | Construction, home appliances, agricultural equipment |

| JIS G3313 | High-strength galvanized steel sheet for applications requiring high strength and corrosion resistance. | Automobiles, industrial equipment, structural parts |

3. EN standard (European standard)

| Grade | Characteristics | Uses |

| EN 10346 | Ordinary galvanized steel sheet with good corrosion resistance and formability | Construction, home appliances, automotive parts |

| EN 10147 | High-strength galvanized steel sheets for applications requiring high mechanical properties | Structural components, industrial equipment |

How is Galvanized steel sheet made?

- Substrate pretreatment: Clean the surface of the steel plate to remove oil, rust and impurities, usually by pickling, alkali washing and other methods to ensure the surface is clean.

- Galvanizing: Immerse the pretreated steel plate in molten zinc liquid to form a uniform zinc coating on the surface of the steel plate; or use electrogalvanizing process to allow zinc ions to adhere to the surface of the steel plate through electrolysis.

- Post-treatment: After galvanizing, cooling, passivation and other treatments are carried out to enhance the adhesion and corrosion resistance of the zinc layer, and finally form a galvanized steel plate.

q195 low carbon steel coil

High Quality Galvanized Coil

4×8 HDP Galvanized-sheet

What are the common steel types for hot-dip galvanized sheets?

According to the standards of different countries, there are different expressions, such as European standard, American standard, national standard and Japanese standard: DX51D, DX52D, DX53D, DC51D, DC52D, DC53D, Q345G, CS Type B, DS Type B, SS Grade 33, SS Grade 40, HSLAS Grade 50, SGCC, SGCH, S250GD, S350GD, S550GD. They correspond to different yield strengths and are used for different purposes.

DX 51 D/DX 52 D/DX 53D/DX 54D Mechanical properties

| Steel grade | Yield strength Re N/mm2, max. | Tensile strength Rm N/mm2 |

| DX 51 D | – | 270 – 500 |

| DX 52 D | 140 – 300 | 270 – 420 |

| DX 53 D | 140 – 260 | 270 – 380 |

| DX 54 D | 120 – 220 | 260 – 350 |

Common galvanized steel grades

- DX51D+Z (EN 10346 standard): DX51D, equivalent to SGCC, is an ordinary galvanized steel sheet with good formability and corrosion resistance. It is used in construction, home appliances, and agricultural equipment.

- SGC400 (JIS G3302): This is a high-strength galvanized steel grade for applications requiring high mechanical properties, such as structural components, automotive, and industrial.

- Q235B+Z (GB/T 2518): China standard ordinary galvanized steel sheet with good corrosion resistance and formability. Mostly used in construction appliances and decorative fields.

- G90 (ASTM A653): High galvanized layer thickness grade, suitable for high corrosive environments. Concentrated on outdoor construction and industrial equipment.

ASTM Regular Spangle Hot Dipped

galvanized checker plate

Corrugated Galvanized Steel Sheet

Galvanized steel sheet composition

The chemical composition is determined by the base material (e.g. mild steel Q95, Q235, low alloy steel S355, S420) and the galvanized layer.

Chemical composition of common galvanized steel grades:

Mild steel galvanized sheet (e.g. Q235B+Z)

| Element | C | Mn | Si | P | S | Al | Zn |

| content | ≤ 0.22% | 0.30%-0.65% | ≤ 0.35% | ≤ 0.045% | ≤ 0.050% | ≥ 0.015% | ≥ 99.0% |

Low alloy steel galvanized sheet (e.g. S355J2+Z)

| Element | C | Mn | Si | P | S | Cr | Ni | Zn |

| content | ≤ 0.20% | 1.00%-1.60% | ≤ 0.55% | ≤ 0.035% | ≤ 0.035% | ≤ 0.30% | ≤ 0.50% | ≥ 99.0% |

Wanzhi Steel Quality Inspection

Quality Control

G60 galvanized steel specification

| Item | G60 galvanized steel |

| Weight of galvanized layer on both sides | 183 g/m² (approx. 91.5 g/m² per side) |

| Weight of galvanized layer on one side | Half of both sides |

| Galvanized layer thickness | Total thickness 20-25 µm on both sides (approx. 10-12.5 µm on each side) |

| Galvanizing process | Hot-Dip Galvanizing |

| Base material | Low Carbon or Low Alloy Steel |

| Chemical Composition | C,Mn,Si,P,S,Al |

| Yield Strength (MPa) | >230 |

| Tensile Strength (MPa) | >300 |

| Elongation (%) | >22 |

G90 galvanized steel

The number 90 stands for the galvanizing quantity, which is 275 g/m² of zinc per square meter. The following scenarios are applicable for different zinc layer weights.

| Galvanized layer grade | Weight of galvanized layer (g/m²) | Galvanized layer thickness (μm) | Applicable Scenario |

| G30 | 90 | 10-12 | General purpose, indoor environment |

| G60 | 183 | 20-25 | Moderately corrosive environments, such as building facades |

| G90 | 275 | 30-35 | Highly corrosive environments, such as coastal areas |

Z275 Galvanized Steel Sheet MS plate

SGCC Z100 Z275 2mm Thick 60g Galvanized Steel Sheet

FAQs

1. Is galvanized better than stainless steel?

In terms of function, the performance of galvanized steel is not as good as that of stainless steel, especially in terms of corrosion resistance. However, in terms of price, stainless steel is more expensive. It is mainly used in high-precision equipment and chloride-containing environments. However, in general environments, galvanized steel is sufficient and has a high cost-effectiveness, making it a good substitute for stainless steel.

2. Does galvanized steel get rusty?

It can last for decades with proper use, but it is always metal and therefore will eventually rust. Therefore, you can choose galvanized steel with more zinc content, in the meantime, please keep it dry and hygienic, scrub it with mild detergent, and avoid direct contact with highly active metals.

3. What are the causes of white rust and black spots?

Black spots are formed by further oxidation of white rust. The main causes of white rust are:

- The thickness of the passivation film is not enough or uneven; passivation principle: Zn+H2GrO4-ZnGrO2=H2.

- The surface is not oiled or there is residual moisture on the steel surface.

- The surface of the strip contains moisture when it is coiled.

- The passivation is not completely dried.

- It is damp during transportation or storage.

- The finished product is stored for too long, more than three months.

Standard Export Package

Inner waterproof kraft paper packaging

Cold rolled EGI galvanized sheet shipped to India

Galvanized steel sheet Manufacturer – Wanzhi Steel

Wanzhi Steel has several galvanized sheet coil production lines and 3 color coating lines, which can simultaneously meet the production and processing of sheet and strip coils. The length and width of our galvanized sheets can be customized.

Get samples or a bulk quote! Chat with Us Online,

or send an email to: info03@wanzhisteel.com.

Wanzhi Steel is an ISO 9001-certified steel factory located in Hebei Province, China. For 14 years, we have been specializing in the production of White corrugated roofing sheet, galvanized flat bar, serrated steel grating, Galvanized Steel Coils, Aluminum zinc magnesium plate, Color Coated Coil, and Galvanized corrugated roofing sheets with a monthly output of 1800 tons. With high-quality products and good services, its products have been exported to more than 120 countries around the world.

| Galvanized steel sheet thickness and theoretical weight table | |||||||

| Plate thickness (mm) | Plate weight (Kg/m2) | Plate thickness (mm) | Plate weight (Kg/m2) | Plate thickness (mm) | Plate weight (Kg/m2) | Plate thickness (mm) | Plate weight (Kg/m2) |

| 0.1 | 0.785 | 0.7 | 5.496 | 3.8 | 29.83 | 19 | 149.2 |

| 0.12 | 0.942 | 0.75 | 5.8875 | 4 | 31.4 | 20 | 157 |

| 0.15 | 1.1775 | 0.8 | 6.28 | 4.2 | 32.97 | 22 | 172.7 |

| 0.18 | 1.413 | 0.9 | 7.065 | 4.5 | 35.325 | 24 | 188.4 |

| 0.2 | 1.57 | 1 | 7.85 | 4.8 | 37.68 | 25 | 196.25 |

| 0.22 | 1.727 | 1.1 | 8.635 | 5 | 39.25 | 26 | 204.1 |

| 0.24 | 1.884 | 1.2 | 9.42 | 5.5 | 43.18 | 28 | 219.8 |

| 0.25 | 1.9625 | 1.3 | 10.21 | 6 | 47.1 | 30 | 235.5 |

| 0.28 | 2.198 | 1.4 | 10.99 | 6.5 | 51.03 | 32 | 251.2 |

| 0.3 | 2.355 | 1.5 | 11.775 | 7 | 54.96 | 34 | 266.9 |

| 0.32 | 2.512 | 1.6 | 12.56 | 8 | 62.8 | 36 | 282.6 |

| 0.35 | 2.7475 | 1.7 | 13.35 | 9 | 70.65 | 38 | 298.3 |

| 0.38 | 2.983 | 1.8 | 14.13 | 10 | 78.5 | 40 | 314 |

| 0.4 | 3.14 | 1.9 | 14.92 | 11 | 86.35 | 42 | 329.7 |

| 0.42 | 3.297 | 2 | 15.7 | 12 | 94.2 | 45 | 353.3 |

| 0.45 | 3.5325 | 2.2 | 17.27 | 13 | 102.1 | 48 | 376.8 |

| 0.48 | 3.768 | 2.5 | 19.625 | 14 | 109.9 | 50 | 392.5 |

| 0.5 | 3.925 | 2.8 | 21.98 | 15 | 117.75 | 52 | 408.2 |

| 0.55 | 4.318 | 3 | 23.55 | 16 | 125.6 | 55 | 431.8 |

| 0.6 | 4.71 | 3.2 | 25.12 | 17 | 133.5 | 58 | 455.3 |

| 0.65 | 5.103 | 3.5 | 27.475 | 18 | 141.3 | 60 | 471 |

Leave Us A Message