Expanded Metal Grating

Material: Galvanized steel, Stainless steel, Mild steel, Carbon steel

Thickness: 1.5.0-8.0mm

Hole Shape: Diamond, Hexagonal, Gothic, Decorative, etc.

Delivery Time: : 15-21 days

Transportation: By sea, by land

Expanded Metal Grating

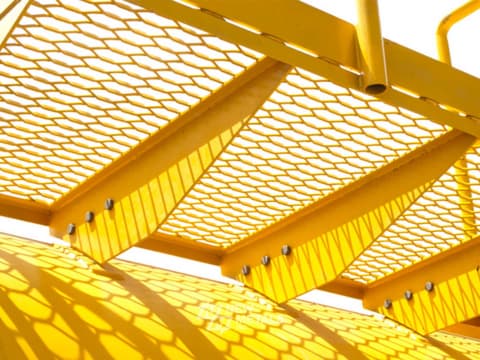

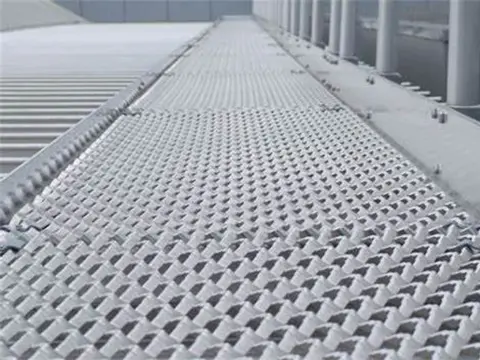

Expanded Metal Grating is manufactured by slitting and stretching a single sheet of metal to maximize the use of the raw material while producing a strong, rigid, and open sheet. It is a lightweight, economical alternative for short span catwalks and maintenance platforms. Available in distinct hexagonal or diamond patterns, standard products are produced with the long way of the opening “spanning” the length (long direction) of the sheet. Wanzhi Steel accepts customized sizes. We have low-carbon steel, galvanized steel, stainless steel, aluminum, and galvalume steel for choice, and provide powder coating and PVC coating services. Welcome to contact us for more information.

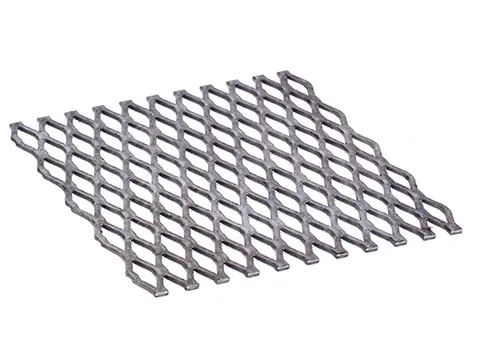

diamond shaped metal grate

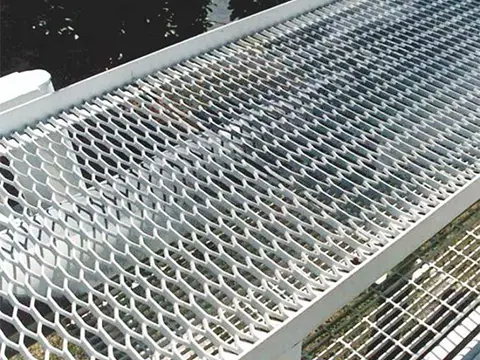

expanded metal catwalk grating

Specification

| Item | Expanded Metal Grating |

| Place of Origin | Hebei, China |

| Standard | AISI, ASTM, DIN, JIS, GB, EN |

| Technique | Perforated |

| Processing Service | Bending, Welding, Cutting, Punching |

| Surface Treatment | Galvanized, PVC Coated, Powder Coated, PVDF |

| Panel Width | 0.5m-2m |

| Panel Length | 1m-6.0m |

| Hole size | 5mm-100mm |

| Color | Silver, white, black, red, green, gray |

| Function | Floor/driveway/sidewalk/catwalk grating, plastering works, building reinforcement |

| Sample | Free Available |

| Payment term | TT 30% Advance + 70% Balance |

| Price Item | FOB, CIF, EXW, CFR, etc |

| Packing | Standard export packaging |

| Certification | ISO 9001, SGS, ABS, BV |

| MOQ | 200 pieces, 5 tons |

What is expanded metal grating?

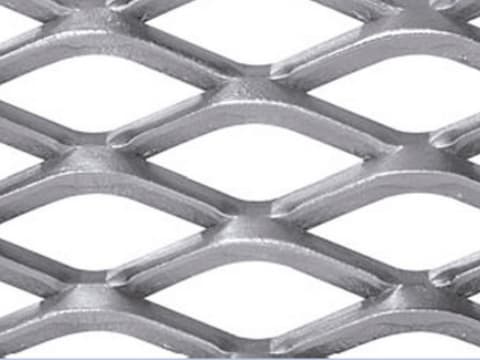

- The expanded steel grating also called expanded metal or expanded metal sheet, is one of the most widely used metal wire mesh products. The expanded metal mesh is produced of a whole metal sheet by punching and expanding process, the material of metal grating sheets can be Mild steel plate, stainless steel plate, carbon steel, GI Steel plate, aluminum plate or galvalume steel plate, nickel plate, etc. For example: expanded aluminum grating and stainless steel expanded metal grating.

Galvanized decorative grating

Expanded Metal Mesh

- The mesh holes of expanded metal mesh are uniform, for instance, the diamond shaped metal grate, and the mesh structure is firm and stable, this makes the mesh achieve very high strength with light weight. Even heavy duty expanded metal grate is only a fraction of the weight of a steel plate.

What is XPM mesh?

It is the abbreviation of expanded metal mesh.,expanded mesh grating is useful for heavyweight custom parts washing applications, as well as providing open space for air flow and drainage.

Advantages

- Excellent comprehensive performance: It has the advantages of both metal plates and metal meshes, with higher strength than fine metal meshes, and better ventilation and drainage than metal plates.

- Strong mechanical properties: The tensile strength is higher than that of metal wire baskets and metal meshes.

- Efficient processing and installation: It reduces welding processes, is easy to cut and bend, and can quickly complete the production of solid baskets, screens, walkways and other products.

- High strength: One-piece mesh structure, strong bearing capacity, not easy to deform and break.

- Good anti-slip performance: The surface texture increases friction, and a variety of styles meet the requirements of anti-slip and light transmission to ensure safety.

- Durable and economical: After galvanizing, it has strong corrosion resistance, long service life, and low maintenance cost; high material utilization rate and affordable.

Expanded Metal Grating of Different Materials

mild steel walkway mesh

stainless steel expanded metal grating

expanded aluminum grating

What is expanded steel grating used for?

Any metal elements or alloys that go through a machining process that cuts and draws that material into an open grid pattern are referred to as expanded steel.

- Architecture, water filtration, and construction companies all use expanded metals to build parts and structures on a budget.

- One of the most common products made from expanded metal is grating. This type of grating is widely used in industrial settings, aisles, and platforms. Typical use is expanded metal catwalk grating. Its open design facilitates efficient drainage and ventilation while providing strong support for heavy objects.

- Fencing and security products. The interlocking pattern of expanded metal mesh is ideal for fencing, providing visibility and security in a variety of environments such as airports, prisons, and commercial properties.

- Architectural mesh made of expanded metal can be used as sunshades, privacy screens, and art installations, allowing designers to creatively manipulate light and shadow.

- Radiator grilles and protective covers.

- Filtration and screening: air filters, oil filters, and screens in various industrial processes to separate particles in liquids and gases.

- Concrete reinforcement mesh can significantly improve the structural integrity and load-bearing capacity of the concrete structure. Expanded metal walkway is also commonly used.

Safety guard

Yellow expansion grille

Stainless steel grille shape

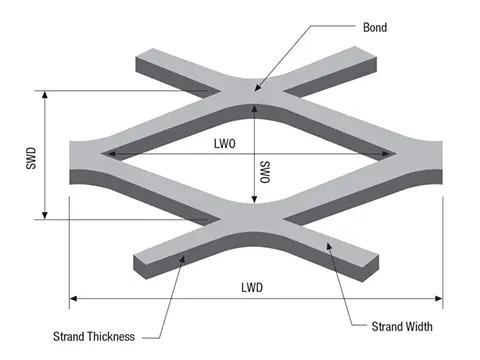

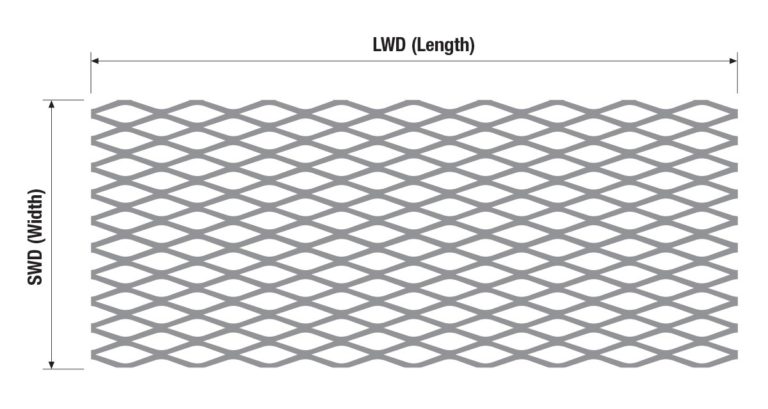

Expanded Metal Terminology

| Name | Expanded metal steel grating |

| Diamond | The open area is formed by stands and bonds. |

| Bond | The point where adjacent strands meet. |

| LWD | The diagonal dimension of the rhombus |

| SWD | Dimensions of the short diagonal of the rhombus |

| LWO | “Long Way of Opening”; Used as a reference point only, to determine a clear opening in the long dimension. |

| SWO | “Short way of the opening” is used as a reference point only to determine a clear opening in the short dimension. |

| Strands | The thickness of the metal in the expanded design. |

| Strand Thickness | The original thickness of the metal before expanding. |

| Strand Width | The amount of metal between diamonds to produce one strand. See the ordering Information at the bottom of the page. |

| Design Size (Style) | The first number designates the nominal diamond pitch short way of design (SWD). The second number used in conjunction with the first number may specify the gauge of metal, weight per hundred square feet, or have some other significance. Therefore, word gauge should never be added to the design size or style. |

expanded metal steel grating

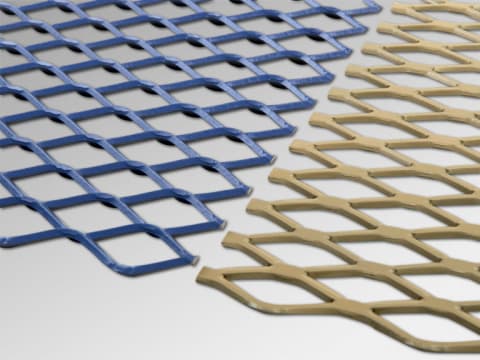

Blue expanded grating

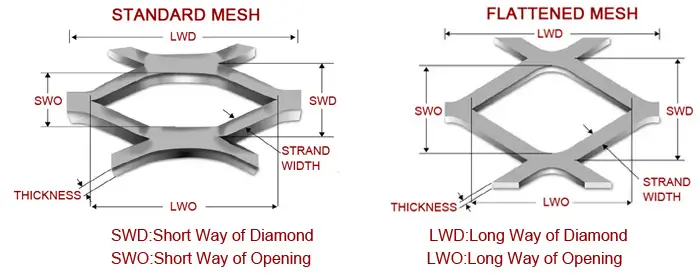

Regular vs. Flattened Expanded Metal

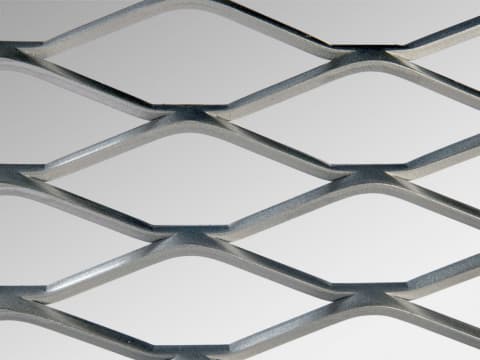

Expanded metal is a cold forming process that stretches and evenly cuts metal sheets; then, holes are opened on the sheet to form regular gaps of different shapes. Regular or standard Expanded Metal will be raised at the diamond-shaped openings, while Flattened Expanded Metal is rolled by rollers, and each joint is smooth and flat. Wanzhi Steel’s expanded metal is a single-piece construction that stays intact even after years of use. It won’t break or disintegrate as it can hold its shape for a long time. It’s available in a raised or a flattened pattern, in different opening sizes, materials, sheet sizes, and gauges.

How to measure a flattened mesh?

The key measurements for a flattened mesh are Longway Aperture (LWA), Shortway Aperture (SWA), Strand Width (SWDT), and Strand Thickness (STK).

| Name | Flattened mesh grating |

| LWA | Measured horizontally from internal aperture point to point. |

| SWA | Measured vertically from internal aperture point to point. |

| SWDT | A measurement of the width of the resulting angular strand created during manufacture. |

| STK | A measurement of starting raw material thickness. |

How to measure raised expanded mesh?

The key measurements for a raised mesh are the Longway Pitch (LWP), Shortway Pitch (SWP), Strand Width (SWDT), and Strand Thickness (STK).

Expanded Metal Grille Character Interpretation

| Name | Raised expanded mesh |

| LWP | Measured horizontally from either knuckle to knuckle or center to center, it is derived from the size of tooling used within the production process. |

| SWP | Measured vertically from either knuckle to knuckle or center to center, it is manifested through the overall expansion applied during manufacture. |

| SWDT | A measurement of the width of the resulting angular strand created during manufacture. |

| STK | A measurement of starting raw material thickness. Contrary to belief, the expanding process does not directly alter material thickness. |

| Note: The strand thickness should not be confused with the overall height or depth of the expanded metal. Typically, the mesh height can be 1-2 times the SWDT measurement. | |

How do I specify sheet size and orientation?

When specifying sheet dimensions, one should also consider the orientation of the diamonds in relation to sheet size. The terminology employed to describe orientation is Longway Mesh (LWM/LWD) and Shortway Mesh (SWM/SWD).

Basic annotation format

Material × stem width (SW) × stem thickness (ST) × long pitch (LWD) × short pitch (SWD) – surface treatment

Example: 304 stainless steel 5mm × 1.2mm × 25mm × 12mm – electrolytic polishing.

The golden rule of direction selection

- Conventional direction (LWD priority): The long side of the diamond is parallel to the rolling direction, and the compressive strength is increased by 30%. It is suitable for building load-bearing layers/mechanical equipment protection, walkway boards/industrial screening.

- Special direction (SWD priority): The short side of the diamond is parallel to the rolling direction, and the surface flatness Ra≤3.2μm is suitable for: curtain wall decoration/precision filtration.

Expansion grating edge type

EXPANDED-METAL-PATTERN-ORIENTATION

Expanded metal grating sizes

| Expanded Metal — Grating & Catwalk Grating Load Table | |||||

| Span | |||||

| Material | Style | Load | 24″ | 36″ | 48″ |

| Carbon Steel | 3.0# | U | 275 | 100 | — |

| D | 0.250 | 0.220 | — | ||

| C | 275 | 165 | 75 | ||

| D | 0.250 | 0.250 | 0.250 | ||

| 3.14# | U | 375 | 150 | 50 | |

| D | 0.250 | 0.240 | 0.250 | ||

| C | 375 | 155 | 75 | ||

| D | 0.250 | 0.250 | 0.250 | ||

| 4.0# | U | 350 | 150 | 50 | |

| D | 0.240 | 0.245 | 0.250 | ||

| C | 440 | 220 | 100 | ||

| D | 0.250 | 0.250 | 0.250 | ||

| 4.27# | U | 500 | 165 | 60 | |

| D | 0.245 | 0.245 | 0.250 | ||

| C | 400 | 225 | 100 | ||

| D | 0.250 | 0.240 | 0.250 | ||

| 5.0# | U | 600 | 175 | 100 | |

| D | 0.240 | 0.240 | 0.250 | ||

| C | 540 | 310 | 140 | ||

| D | 0.245 | 0.250 | 0.250 | ||

| 6.25# | U | 800 | 300 | 115 | |

| D | 0.220 | 0.250 | 0.240 | ||

| C | 800 | 300 | 150 | ||

| D | 0.220 | 0.240 | 0.240 | ||

| 7.0# | U | 800 | 400 | 165 | |

| D | 0.210 | 0.250 | 0.240 | ||

| C | 800 | 350 | 175 | ||

| D | 0.220 | 0.240 | 0.250 | ||

| Aluminum | 2.0# | C | 250 | 100 | 50 |

| D | 0.250 | 0.250 | 0.250 | ||

| Stainless Steel | 3.3# | C | — | 150 | 50 |

| D | — | 0.197 | 0.135 | ||

| 4.5# | C | 300 | 150 | 100 | |

| D | 0.217 | 0.192 | 0.212 | ||

| U – Uniform Load in Lbs. per Sq. Ft.

C – Mid-span Concentrated Load in Lbs. per Sq. Ft. D – Deflection in inches. |

|||||

| NOTE: The values presented in this table were measured with the test specimens securely welded to a supporting frame prior to the imposition of load. Testing further indicates that if the test specimens are not so welded, the capacity of the grating is greatly reduced. | |||||

grated metal sheet

Decorative Metal Sheets

expanded metal floor grating

FAQs

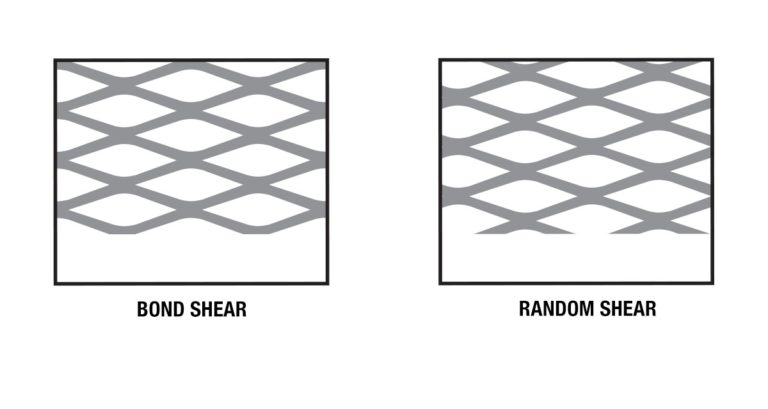

1. Shearing Expanded Metal Grating Method

- Bond Shear: The expanded metal sheet is cut through the center of the bonds, resulting in a closed diamond at the edge of the sheet.

- Random Shear: The expanded metal sheet is cut through diamond,s resulting in partial diamonds at the sheet’s edge. The partial diamonds result in exposed strands that are very sharp and should be protected with U-Edging or framing.

2. How strong is expanded metal?

Because of its safe structure, it is durable and offers strong impact resistance. Provides sound insulation. In addition, it is designed in one piece without welding or additions and provides effective durability. Expanded metal is easily assembled at the weight point due to its lightness, according to its dimensions.

3. Why is it called expanded metal?

Because expanded metal is made from a solid sheet of metal and is not woven or welded, it can never unravel. To produce expanded metal, a sheet or plate is simultaneously slit and stretched. This process expands the cuts into diamond-shaped holes of uniform size and shape.

metal mesh walkway

expanded metal walkway mesh

Stair partition

4. How do you calculate the open area of expanded metal?

Percent Open Area — The total open area of an expanded metal blank or coil. To calculate the Percent Open Area: take two times the strand width, divide by the SWD, and then take the inverse number.

Wanzhi Steel Factory

- Fully automatic manufacturing: CNC stretching equipment can process 1.5-12mm thick plates of various materials, with a maximum width of 3.2 meters and a hole spacing accuracy of ±0.5mm.

- Heavy load-bearing: Produces 6-meter large-span industrial-grade grilles in accordance with EN ISO 14122 standards, with optional anti-slip tooth design and 30% increased bending strength.

- Customized service: Supports special-shaped cutting and special surface treatment to meet the personalized needs of various projects.

- Efficient global supply: Large inventory of conventional sizes, and has completed the supply of 500,000 square meters of high-end projects, covering petrochemical, power, and other fields.

Galvanized expanded metal lath mesh

Green expanded grating

low carbon steel expanded mesh sheet

Expanded Metal Grating Manufacturer – Wanzhi Steel

Wanzhi Steel specializes in the production of high-quality expanded metal gratings, made of high-quality low-carbon steel, stainless steel, and aluminum-magnesium alloy. It is suitable for industrial platforms, trail fences, and architectural decoration. It supports precision laser cutting, anti-slip tooth shape, surface galvanizing/spraying and other process customization. Standard delivery time is 15-21 days, providing professional technical support and engineering solution design.

Get samples or a bulk quote! Chat with Us Online,

or send an email to: info03@wanzhisteel.com.

Wanzhi Steel is an ISO 9001-certified steel factory located in Hebei Province, China. For 14 years, we’ve been specializing in the production of stainless steel grating, Steel Grating Plate, aluminum bar, Diamond Mesh Lath, serrated steel grating, Galvanized expanded metal lath, sidewalk grating, grating platform, and grating floor with a monthly output of 1800 tons. With high-quality products and good services, its products have been exported to more than 120 countries around the world.

Leave Us A Message

- Galvanized Concrete Mesh

- Perforated stainless steel mesh

- Galvanized expanded metal mesh

- Galvanized Grating

- Diamond Mesh Lath

- Galvanized Expanded Metal Lath

- Diamond Mesh Lath

- Expanded Metal Grating

- Steel Grating Plate

- Welded Wire Fabric

- Wire Mesh For Concrete Slab

- Galvanized Concrete Mesh

- Galvanized Grating For Sale