DX51D

DX51D is a grade of cold rolled low carbon steel sheet and strip. Originating from the European Industrial Standard (EN), some domestic steel mills also use this grade as their corporate standard. Sometimes SGCC appears at the same time as it. For most professional steel practitioners, SGCC and DX51D can replace each other under the premise of certain consistent delivery requirements. DX51D steel is mainly used for manufacturing cold-formed steel, welded steel pipe, automobile bodies, automobile parts, building structures, general steel plate components, etc. This steel has a specific chemical composition and mechanical properties, excellent stamping performance, welding performance, and surface quality, and can meet various cold forming requirements. It meets the needs of a variety of applications.

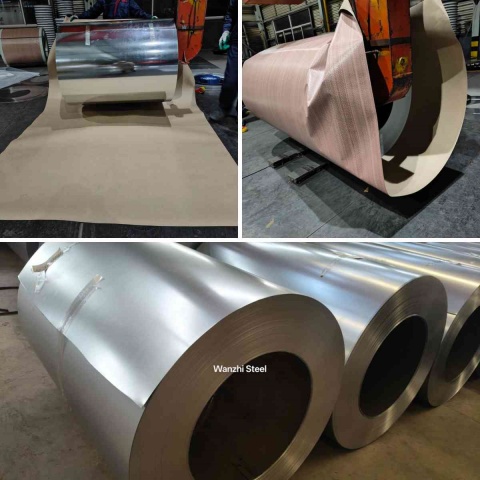

0.12-4.0mm DX51D Z60 Z100 HDG Coil

DX51D Steel Coil

Hot dip galvanized steel coil strips

Material Characteristics

It has good plasticity, toughness, welding performance, and cold forming performance, and its yield strength is moderate, which is conducive to stamping and other processing processes. In addition, the DX51D steel plate also has good corrosion resistance and is suitable for use in a variety of environments.

Surface Quality

The surface quality is usually high, without obvious defects such as cracks, inclusions, bubbles, etc. This helps to ensure the reliability and durability of the steel plate during subsequent processing and use.

Processing Performance

It has good stamping performance and welding performance, and is suitable for various cold forming processes such as stamping, bending, stretching, etc. At the same time, it can also match various welding methods, such as resistance welding, gas-shielded welding, etc.

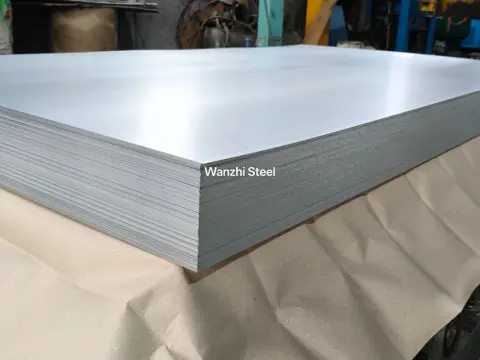

Hot-dip galvanized steel sheet 48

Hot-dip galvanized steel sheet zero spangle

| Grade | DX51D |

| European standard steel grade | 1.0917 |

| Corresponding standard | EN 10346-2015 |

| Classification | Continuously hot-dip coated steel flat products for cold forming – Technical delivery conditions |

Mechanical Properties of DX51D Steel

| Item | Nominal gauge, mm | Minimum yield strength, ReH (σbMpa) | Minimum elongation ratio δ, % |

| Hot dip galvanized steel sheet | 0.57-2.00 | 270-500 | A80: ≥22 |

The minimum elongation applies to the following thicknesses, t represents the thickness of the plate:

1). 0.5mm < t ≤ 0.7mm, the minimum elongation is 2% less than the value in the table;

2). 0.35mm < t ≤ 0.5mm, the minimum elongation is 4% less than the value in the table;

3). t ≤ 0.35mm, the minimum elongation is 7% less than the value in the table.

Dx51d Z100 Galvanized steel Plate

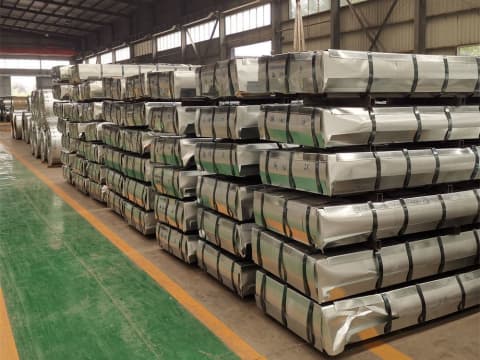

Best Selling Roll of Galvanized Steel

galvanized steel coil wholesaler

Chemical Composition of DX51D Steel, %

| С | Si | Mn | P | S | Ti |

| ≤0.18 | ≤0.5 | ≤1.2 | ≤0.12 | ≤0.045 | ≤0.03 |

Chemical Composition & Mechanical Properties According to EN 10346

In fact, combining the above ingredients and properties gives us the following table, which summarizes the chemical and mechanical properties.

| Steel grade number | Coating symbol | Chemical composition (Ladle analysis), max. % | Mechanical properties | ||||||

| C | Si | Mn | P | S | Ti | Tensile strength, Rm, MPa | Elongation A80, min. % | ||

| 1.0226 | +Z | 0.18 | 0.50 | 1.20 | 0.12 | 0.045 | 0.30 | 270-500 | 22 |

Material Comparison

| Chinese Standards | Japanese Standard | European Standards |

| DX51D+Z/DC51D+Z (CR) | SGCC | DX51D+Z |

| DX52D+Z/DC52D+Z | SGCD1 | DX52D+Z |

| DX53D+Z/DC53D+Z/DX54D+Z/DC54D+Z | SGCD2/SGCD3 | DX53D+Z/DX54D+Z |

| S220/250/280/320/350/550GD+Z | SGC340/400/440/490/570 | S220/250/280/320/350GD+Z |

| DX51D+Z/DD51D+Z (HR) | SGHC | DX51D+Z |

Application

It is commonly used in the construction industry for facade and roofing materials, including flues, corrugated panels, gutters, and all systems exposed to high humidity. Also in switch cabinets, the electrical industry, ventilation technology, and air conditioning systems, it is used in agricultural equipment in silos and barns, as well as in steel furniture.

Oil and gas structural parts

standing seam metal roof

GI STEEL FRAMING FOR OUTDOOR STRUCTURE

Analogues to DX51D Steel

| US (AISI, ASTM, ASME) | ASTM A653/A653M Class B |

| Germany (DIN) | 1.0322, 1.0335, DC01, DC04, DC04G1, DD11, DD13, St12, St14, St22, StW24, USt3, USt4 |

Different Grades, Different National Standard Chemical Composition Table

| Standard | Grade | C | Si | Mn | P | S | Ti |

| For cold forming

Chinese standard

|

DX51D+Z | 0.12 | 0.50 | 0.60 | 0.100 | 0.045 | 0.30 |

| DX52D+Z | 0.12 | 0.50 | 0.60 | 0.100 | 0.045 | 0.30 | |

| DX53D+Z | 0.12 | 0.50 | 0.60 | 0.100 | 0.045 | 0.30 | |

| DX54D+Z | 0.12 | 0.50 | 0.60 | 0.100 | 0.045 | 0.30 | |

| DX56D+Z | 0.12 | 0.50 | 0.60 | 0.100 | 0.045 | 0.30 | |

| DX57D+Z | 0.12 | 0.50 | 0.60 | 0.100 | 0.045 | 0.30 | |

| For cold forming

Japanese standard |

SGCC | 0.15 | 0.50 | 0.80 | 0.050 | 0.030 | 0.025 |

| SGCD1 SGCD2 |

0.12 0.10 |

0.50 0.50 |

0.60 0.45 |

0.040 0.030 |

0.030 0.030 |

0.025 0.025 |

|

| SGCD3 | 0.08 | 0.50 | 0.45 | 0.030 | 0.030 | 0.025 | |

| SGCD4 | 0.06 | 0.50 | 0.45 | 0.030 | 0.030 | 0.025 | |

| For structures

Japanese standards |

SGC340 | 0.25 | 0.50 | 1.70 | 0.200 | 0.035 | 0.025 |

| SGC400 SGC440 |

0.25 0.25 |

0.50 0.50 |

1.70 2.00 |

0.200 0.200 |

0.035 0.035 |

0.150 0.150 |

|

| SGC490 | 0.30 | 0.50 | 2.00 | 0.200 | 0.035 | 0.025 | |

| SGC510 | 0.30 | 0.50 | 2.50 | 0.200 | 0.035 | 0.025 | |

| For structures

AISI standards |

S220GD+Z | 0.20 | 0.60 | 0.70 | 0.100 | 0.045 | 0.025 |

| S250GD+Z | 0.20 | 0.60 | 0.70 | 0.100 | 0.045 | 0.025 | |

| S280GD+Z | 0.20 | 0.60 | 0.70 | 0.100 | 0.045 | 0.025 | |

| S320GD+Z | 0.20 | 0.60 | 0.70 | 0.100 | 0.045 | 0.025 | |

| S350GD+Z | 0.20 | 0.60 | 0.70 | 0.100 | 0.045 | 0.150 | |

| S550GD+Z | 0.20 | 0.60 | 0.70 | 0.100 | 0.045 | 0.150 |

Z100 galvanized steel coils shipped to Kenya

G90 GI steel coil shipped to Kazakhstan

Z150 GI steel coil shipped to Chile

DX51D And Other Grades’ Mechanical Properties

| Grade | Yield strength MPa≥ | Tensile strength MPa≥ | Elongation A%≥ |

| DX51D+Z/ZM/AZ/AM | 240-380 | 270-500 | 22 |

| DX52D+Z/ZM/AZ/AM | 140-300 | 270-420 | 26 |

| DX53D+Z/ZM/AZ/AM | 140-260 | 270-380 | 30 |

| DX54D+Z/ZM/AZ/AM | 120-220 | 260-350 | 36 |

| S220GD+Z/ZM/AM | 220 | 300 | 20 |

| S250GD+Z/ZM/AZ/AM | 250 | 330 | 19 |

| S280GD+Z/ZM/AM | 280 | 360 | 18 |

| S300GD+AZ/AM | 300 | 380 | 18 |

| S320GD+Z/ZM/AM | 320 | 390 | 17 |

| S350GD+Z/ZM/AZ/AM | 350 | 420 | 16 |

| S450GD+AZ/AM | 450 | 480 | 15 |

| S550GD+Z/ZM/AZ/AM | 550 | 550 | - |

Surface Treatment Type

Generally, the galvanized sheets and coils produced will be surface treated to improve corrosion resistance and paint adhesion, which is a way to protect the steel surface. The following are 8 surface treatment methods.

| Surface treatment type | Code | Features |

| Chromic acid treatment | C | Good corrosion resistance, suitable for an exposed state |

| Chromic acid treatment + oiling | S | Good corrosion resistance |

| Phosphoric acid treatment (including sealing treatment) | P | It has certain corrosion resistance and good paint performance |

| Phosphoric acid treatment (including sealing treatment) + oiling | Q | It has a certain degree of corrosion resistance, good paint performance, prevents rust during transportation and storage |

| Phosphoric acid treatment (excluding sealing treatment) | T | It has certain corrosion resistance and good paint performance |

| Phosphoric acid treatment (excluding sealing treatment) + oiling | V | It has certain corrosion resistance, good paint performance, and prevents rust |

| Oiling | O | Prevent rust during transportation and storage |

| No treatment | M | Suitable for immediate painting |

How Much Does It Cost?

Due to different plate thickness and surface treatment processes, as well as different order quantities, the price of DX51D is about 564 dollars/ton to 846 dollars/ton, which is a more common price range in the market and applies to most specifications of DX51D steel plates.

Some DX51D plates with lower quality grades and smaller specifications have lower prices, about 423 dollars/ton to 563 dollars/ton.

For accurate prices please contact professional technicians

and calculate the price based on the size.

Summary

In summary, the Dx51D steel plate is a kind of cold-rolled low-carbon steel plate and strip with excellent performance and wide application. Determine the appropriate thickness, specification, and performance level according to the specific environment and requirements. If you still have questions about DX51D, The online manager will answer your questions promptly, you can also leave us a message.

0.5mm Thick 120 Gsm Galvanized Iron Sheet

Bwg32/28/34Gauge Zinc Coated plate

Z275 Galvanized Steel Coil Supplier

Dx51d Galvanized Steel Coil & Sheet Manufacturer- Wanzhi Steel

Wanzhi Steel is dedicated to providing high-quality DX51D galvanized and galvanized steel. We offer customization of zinc coating weight, thickness, and coil weight to meet diverse customer needs. Located in Boxing County, Shandong Province, our ISO9001-certified factory boasts two hot-dip galvanizing lines, three color-coating lines, and one electrogalvanizing line. Leveraging advanced technology, strict quality control, and comprehensive customer service, our products are exported to over 120 countries worldwide.

Whether it’s galvanized steel coils/sheets/strips or PPGI/PPGL coils, we can meet your needs.

Get samples or a bulk quote! Chat with Us Online,

or send an email to: info03@wanzhisteel.com

Leave Us A Message