304 VS 316 Stainless Steel

As a widely used alloy material, stainless steel plays an important role in many fields. Among the many types of stainless steel, 304 and 316 stainless steel are the two most common austenitic stainless steels. Both have excellent rust resistance. One is positioned as a “food grade” metal, called “universal grade stainless steel”, commonly known as “white iron” in Taiwan, China. The other is positioned as a “marine grade” metal, called “the noble among stainless steels”, corresponding to 304 and 316 stainless steels. Both are widely used in medicine, food, chemicals, home decoration, etc. This article will compare 304 stainless steel and 316 stainless steel in detail from the aspects of definition, composition, characteristics, performance, price and use, in order to provide you with a comprehensive understanding and selection reference.

Kitchen Utensils

316 Stainless Steel Cleat Mooring Bollard

17-4PH Martensite-Marine Engineering

Chemical composition comparison

The main difference between 304 and 316 stainless steel is their chemical composition, especially the addition of molybdenum (Mo) element.

|

Elements |

304 stainless steel (%) | 316 stainless steel (%) |

Effects |

|

Carbon (C) |

≤0.08 |

≤0.08 |

Increase hardness, but an excessive amount will reduce corrosion resistance |

|

Silicon (Si) |

≤1.00 | ≤1.00 |

Increase high-temperature oxidation resistance |

|

Manganese (Mn) |

≤2.00 | ≤2.00 | Increase strength and processing performance |

| Phosphorus (P) | ≤0.045 | ≤0.045 |

Excessive amounts will reduce the toughness |

|

Sulfur (S) |

≤0.030 | ≤0.030 | Excessive amounts will reduce corrosion resistance |

|

Chromium (Cr) |

18.0-20.0 | 16.0-18.0 |

Form a passivation film to improve corrosion resistance |

| Nickel (Ni) | 8.0-10.5 | 2.0-3.0 |

Stabilize austenite structure, improve toughness and corrosion resistance |

|

Molybdenum (Mo) |

None | 2-3 | Significantly improve pitting and crevice corrosion resistance, especially in chloride environments |

| Nitrogen (N) | ≤0.10 | ≤0.10 |

Increase strength and corrosion resistance |

316l ss steel coil

304 stainless steel sheet 4×8

cold-rolled-304 stainless pipe

|

Differences between stainless steel grades |

|

|

304 stainless steel: 06Cr19Ni10 |

316 stainless steel: 0Cr17Ni12Mo2 |

Theoretical weight calculation formula

304 stainless steel plate

Length x width x thickness x 7.93g/cm³ = weight

316 stainless steel plate

Length x width x thickness x 8.03g/cm³ = weight

Stainless steel round tube

0.02466*wall thickness* (outer diameter-wall thickness) x length = weight

Stainless steel square tube

(side width x4÷3.14-thickness) x thickness x 0.02491 = weight

316-Stainless-Steel-Coil

316 stainless steel tube

1.4301 stainless

Definition

Both 304 stainless steel and 316 stainless steel are austenitic stainless steels. They have similar crystal structures, which makes them similar in processing performance, toughness, and weldability.

However, by adding different alloying elements, these two stainless steels show different characteristics in corrosion resistance, heat resistance, and applicable environment.

304 stainless steel

Also known as 18/8 stainless steel in the industry.

It contains about 18% chromium and 8% nickel.

It is one of the most widely used stainless steel and is widely used in industry and furniture decoration industry due to its good comprehensive properties.

316 stainless steel

As an upgraded version of 304 stainless steel, 2-3% molybdenum is added to the composition.

This addition significantly improves its corrosion resistance in certain environments, especially in the presence of chlorides (such as salt water).

magnetic stainless steel sheet

Property

Both have good processing properties, are easy to cut, bend, and weld, have smooth surfaces, are easy to clean, and are scratch and wear resistant, but there are differences in the following aspects:

1. Hardness and strength

316 stainless steel has slightly higher hardness and strength, but the difference is not significant.

2. Density

316 has a slightly higher density, but the impact is small in practical applications. The same density value can sometimes be used to calculate weight.

3. High temperature resistance

316 stainless steel has better high temperature tolerance, with a maximum temperature resistance of 925°C, while 304 stainless steel has a maximum temperature resistance of 870°C.

4. Corrosion resistance

316 contains 2-3% molybdenum, while SS 304 does not, which determines that 316 has better resistance to crevice corrosion and pitting corrosion, even in marine or other chloride environments.

304 stainless steel square tube

Hexagonal Stainless Steel Bar

3 16 stainless steel rod

Corrosion resistance comparison

| 304 stainless steel | 316 stainless steel |

| Good corrosion resistance in most environments, especially in oxidizing media | The corrosion resistance in chloride environment is significantly better than 304 stainless steel |

| Can resist corrosion from ordinary atmosphere, fresh water, steam and weak acid media | It has better corrosion resistance in acidic media such as sulfuric acid, phosphoric acid, and acetic acid |

| Chloride environments (such as seawater, salt water) are prone to pitting and crevice corrosion | It performs well in marine environments, chemical equipment, and high temperature and high humidity environment |

Mechanical properties comparison

The mechanical properties of 304 and 316 stainless steel are similar, with slight differences in some aspects.

| Performance parameters | 304 stainless steel | 316 stainless steel |

| Tensile strength | ≥515 MPa | ≥515 MPa |

| Yield strength | ≥205 MPa | ≥205 MPa |

| Elongation | ≥40% | ≥40% |

| Hardness (Brinell hardness) | ≤201 HB | ≤217 HB |

| Density | 7.93 g/cm³ | 7.98 g/cm³ |

304 2B Finished Stainless Steel Sheet Roll strip coil

thinnest stainless steel sheet supply

hairline finish stainless

Application Comparison

| Industry | 304 stainless steel | 316 stainless steel |

| Construction and decoration | Indoor and outdoor decoration, railings, doors and windows | Decoration in extreme environments, such as building facades on the seaside |

| Chemical industry | Ordinary industrial storage tanks, pipelines, heat exchangers | Reactors, storage tanks, pipelines, valves, especially in highly corrosive media |

| Food processing | Storage tanks, pipelines, conveyor belts, suitable for non-corrosive environments | High-demand food processing equipment, high-precision equipment |

| Furniture and home appliances | Kitchen equipment, tableware, washing machines, refrigerators, etc. | – |

| Medical industry | Surgical instruments, dental instruments | Surgical instruments, implants, dental equipment, pacemakers, joint replacements, etc. |

| Marine engineering | – | Submarine pipelines, seawater desalination equipment, ship parts, offshore platforms |

| Automotive industry | Exhaust systems and body structures | – |

| Conclusion: 304 stainless steel is suitable for ordinary environment and general industry, 316 stainless steel is suitable for highly corrosive environment and high-end applications. | ||

Marine Engineering

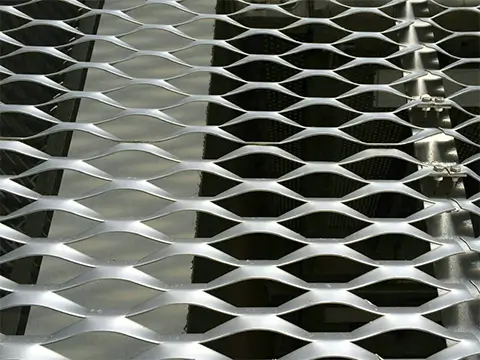

Stainless steel expanded decotion mesh sheet

aisi 304 material storage tank

Price Comparison

The price of 316 stainless steel is usually higher than that of 304 stainless steel. The main reasons are as follows:

1. Molybdenum cost: 316 stainless steel contains 2-3% molybdenum, which is an expensive alloying element.

2. Production process: The production process of 316 stainless steel is more complicated, which increases the cost.

According to market conditions:

– 304 stainless steel: The price per ton is about 2000-3000 US dollars.

– 316 stainless steel: The price per ton is about 3000-6000 US dollars.

Conclusion:

– If the budget is limited and the application environment is not harsh (such as kitchen equipment, or architectural decoration), 304 stainless steel is a more economical choice.

– If higher corrosion resistance and performance are required (such as medical equipment, and food processing equipment), 316 stainless steel is worth investing.

Here is the video we shot in the factory for your reference:

Summary

304 and 316 stainless steel each have their own advantages. Which material to choose depends on the specific application, environment, and budget. Here are the selection suggestions:

In general environments, 304 is sufficient and more cost-effective. In highly corrosive environments (such as marine, chemical) or high-end precision equipment, 316 stainless steel is more suitable.

stainless steel coil wire

stainless steel sheet suppliers

stainless steel coil wire

Which material is chosen, proper use and maintenance can extend its service life and maximize its performance. I hope this article can help you better understand the difference between 304 and 316 stainless steel and choose the most suitable material for your project.

If you have other questions, don’t hesitate to Get In Touch With Us.

( Inquire Online or send an email to Info03@wanzhisteel.com.)

Leave Us A Message