What Is Welded Wire Fabric?

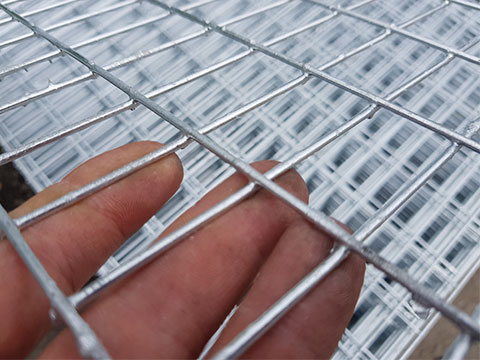

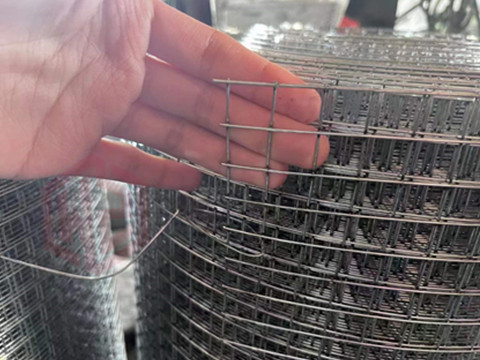

Galvanized Welded Wire Fabric

Welded Wire Fabric

Advantages Of Welded Wire Fabric In Concrete

1. Good Anti-cracking Performance

It can prevent cracks in wall and floor slabs. This is because when a wall or floor slab shrinks or is pulled, the steel resists these tensile stresses. They distribute them evenly over a large area, helping them to hold tightly together and thus minimize cracks.

2. Higher Strength

Compared to manually assembled rebar, this welded wire mesh made of high-quality low-carbon iron wire welded by the machine is much stronger. The mesh stays where you place it and adheres well to the concrete.

3. Economical and Practical

The economy is a very important advantage of it. This is because there is no need to cut rebar, mark, and space it when using welded wire fabric. In addition, you do not need to tie the ties laboriously. This means less reliance on on-site manpower, which saves a lot of labor and time.

4. No Need for Frequent Maintenance

Using a welding wire fabric can in a sense eliminate some of the maintenance work and inspections you have to perform. This is because it always stays in good condition. Besides, it minimizes cracks, making it a good choice for concrete reinforcement.

5. Easy Handling and Placement

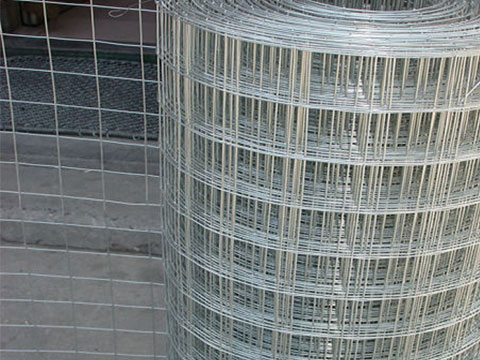

It can be supplied not only in sheet form. In the case of welding wire cloth made from finer wire, it can be supplied in long rolls. This makes it easier to transport and handle. In addition, it will save more space when stored.

6. Avoiding Steel Waste

It is also quick and easy to lay. When using it, you can change the rebar size and spacing. You can reduce steel waste by providing the exact rebar size where it is needed.

Welded Wire Fabric in Roll

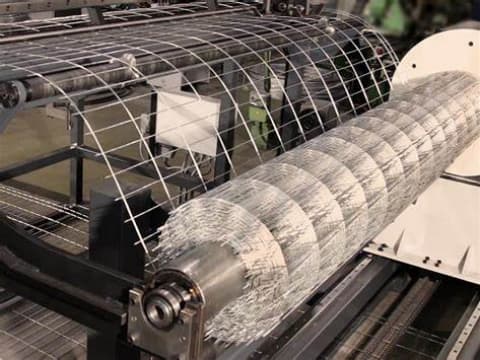

Welded Wire Fabric Factory

What is welded wire fabric used for?

Welded wire mesh is widely used due to its durability, high strength, and versatility, and it can maintain its shape and help reinforce it in various applications. Common uses include the reinforcement of concrete structures, fences, cages, racks, and grilles. Each application requires a specific type of welded wire mesh to meet specific conditions.

The following is a summary of the main ones:

1. Fabrication of frames;

2. Reinforcement of road surfaces or parking lots;

3. Manufacture of various fences;

4. Used as masonry mesh;

5. Used as coal mine roadway support netting.

Construction Use

Fencing

What are the common sizes of welded wire fabric?

Welded wire fabric / Reinforcement Wire Mesh comes in a range of gauges and sheet sizes. In the reference table below, we list the most commonly requested wire mesh sizes that we keep in stock. Mesh gauges and sizes not shown on the table can be specially ordered.

Welded Wire Reinforcement Reference Table

| Style | Gauge | Width/ Length | Unit Weight (lbs) | Package Bundles | Truckload Quality |

| 6×6 4/4 | 4/4 | 8’x 15’ | 67.26 | 50 Sheets | 700 |

| 6×6 2.9/2.9 | 6/6 | 5’x 10’ | 20.69 | 100 Sheets | 2300 |

| 6×6 2.9/2.9 | 6/6 | 8’x 15’ | 48.76 | 50 Sheets | 950 |

| 6×6 2.1/2.1 | 8/8 | 5’x 10’ | 14.98 | 100 Sheets | 3000 |

| 6×6 W1.4/W1.4 | 10/10 | 5’x 10’ | 9.99 | 100 Sheets | 3500 |

| 6×6 W1.4/W1.4 | 10/10 | 8’x15’ | 23.54 | 100 Sheets | 2000 |

| 6×6 W1.4/W1.4 | 10/10 | 5’x150’ | 149.81 | 18 Rolls | 324 |

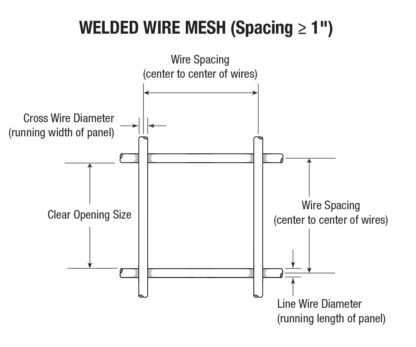

How do you specify welded wire fabric?

Welded wire reinforcement is designated by two numbers and two letter-number combinations. An example is 6×8 – W8 x W4. The first number gives the spacing in inches of the longitudinal wires. The second number gives the spacing of the transverse wires in inches. Below is a detailed interpretation.

How-to-Read-welded-wire-mesh-Sizes

How to read welded wire mesh sizes?

“W” represents smooth wire, “D” represents deformed wire. The number following the letter indicates the cross-sectional area of the wire in hundredths of a square inch. Welded wire fabric is designated by four components: two numbers representing the spacing of longitudinal and transverse wires and two letter-number combinations representing the type and size of longitudinal and transverse wires.

For example, in “6 by 8—W8.0 by W4.0”,

6: spacing of longitudinal wires,

8: spacing of transverse wires,

W8.0: smooth wire with 0.08 square inch cross-sectional area (longitudinal),

W4.0: smooth wire with 0.04 square inch cross-sectional area (transverse).

galvanized welded wire fabric

Common stock sizes: Here are some examples:

Rolls

– 6×6—W1.4xW1.4 (formerly 6×6—10×10)

– 6×6—W2.0xW2.0 (formerly 6×6—8×8)

– 6×6—W2.9xW2.9 (formerly 6×6—6×6)

– 6×6—W4.0xW4.0 (formerly 6×6—4×4)

– 4×4—W1.4xW1.4 (formerly 4×4—10×10)

– 4×4—W2.0xW2.0 (formerly 4×4—8×8)

– 4×4—W2.9xW2.9 (formerly 4×4—6×6)

– 4×4—W4.0xW4.0 (formerly 4×4—4×4)

Sheets

– 6×6—W2.9xW2.9 (formerly 6×6—6×6)

– 6×6—W4.0xW4.0 (formerly 6×6—4×4)

– 6×6—W5.5xW5.5 (formerly 6×6—2×2)

– 4×4—W4.0xW4.0 (formerly 4×4—4×4)

Why WWF is Necessary, what is its purpose?

As mentioned in the first paragraph, it is mainly used in the construction field. The reason for its adoption is that it uses stainless steel bars or galvanized steel bars for electrofusion welding. In addition to their excellent corrosion resistance, they can be used in wet conditions. Customized sizes have precise and neatly arranged grids.

The wire complies with the IS:432-Pt II/1982 standard, which stipulates an ultimate tensile strength of 570 N/mm2 and a characteristic strength of 480 N/mm2. The structural behavior of the welded wire mesh is the same as that of HYSD bars or ordinary mild steel bars. Each rigid weld can resist stresses up to 210 N/mm2, ensuring rapid and complete transfer of stresses in the 2 welded joints of critical sections.

1. The purpose is to bond the concrete better,

2. The strong mechanical anchoring of the weld at each intersection and the close spacing of the fine wires can also effectively resist cracking,

3. It is not as troublesome as cutting steel bars,

4. The step of tying the wires is also omitted

5. Welded wire fabrics provide an ideal and convenient solution for various repair works by re-plastering or spraying.

What Is A Welded Wire?

Welded wire mesh, or welded wire fabric, or “weldmesh” is an electric fusion welded prefabricated joined grid consisting of a series of parallel longitudinal wires with accurate spacing welded to cross wires at the required spacing.

What Is Steel Wire Fabric?

Industrial wire cloth (also referred to as woven metal) is a metal fabric, produced by weaving metal wires together. It’s manufactured in several weave styles, with many different combinations of wire diameters and aperture sizes.

stainless steel welded wire facric

Welded Wire Mesh Roll

How much does Welding Wire Fabric cost?

The cost of welding wire fabric varies depending on the type of wire, material composition, gauge (thickness) of the wire, and quantity purchased. Here are some general price ranges and considerations:

1. Type and Material

Stainless Steel Welding Wire: Stainless steel wire can range in price from $20 to $200 per kilogram, or even higher, depending on grade and quality.

Low Carbon Iron Wire (for Welding Mesh): Low carbon iron wire used in welding mesh can be more affordable, typically ranging from a few dollars to tens of dollars per kilogram, depending on gauge and quantity.

2. Gauge (Thickness)

Thicker wire is usually more expensive than thinner wire due to the increased material content.

The gauge of the wire can also affect welding performance and application, so it is important to choose the right gauge for your specific needs.

3. Brand and Quality

Premium brands and high-quality welding wires are usually more expensive.

However, choosing a reputable brand can ensure better welding performance, reliability, and longer life.

4. Quantity

Buying in bulk can often reduce the unit cost. Many suppliers offer discounts for large orders.

5. Customization

If you require custom wire fabric, such as specific size, hole shape, or surface treatment, this may increase the cost.

However, customization can add value to your wire fabric and meet unique application requirements.

It is important to note that these price ranges are estimates and can vary greatly based on the factors listed above.

For a more accurate quote, it is recommended to contact our professional online staff directly.

A detailed quote can be provided based on your needs.

Custom sizes can also be produced based on customer needs or project requirements

Welding Wire Fabric Coating: The choice of coating depends on the industry, climate, and specific application. The most common coatings produced by Wanzhi Steel are the following 3:

square welded wire mesh

▪ Galvanized weld wire fabric

Electro-galvanized (cold galvanizing) or hot-dip galvanizing. Depending on the name of the process, the mesh is called galvanized welded mesh or hot-dip galvanized welded mesh. The amount of zinc is measured in grams per square meter (GSM) or the thickness of the zinc coating. There are several other common names in the market, such as commercial galvanizing, industrial galvanizing, and heavy-duty galvanizing, which refer to different amounts of zinc per unit. The galvanizing process increases the strength, rigidity, and durability of the mesh.

▪ Powder coated, epoxy coated welded wire fabric

For an added decorative touch, powder coating can be used. Powder coating is a dry finishing process where a fine powder (usually made of polyester, epoxy, or a combination of both) is electrostatically applied to the welded wire mesh. The powder particles attract the welded wire mesh due to electrostatic attraction. Electric or gas furnaces are the equipment to heat the welding mesh and powder coating particles, which will melt and fuse perfectly and firmly with the wire mesh.

▪ PVC coated welded wire fabric

Due to the chemical reaction that produces long molecular chains, the wire mesh’s resistance to chipping, scratching, and corrosion is improved. The coating makes it resistant to environmental factors, chemical corrosion, and abrasion.

In addition, the coated welded wire fabric produced by Wanzhi Steel has different color ranges, selected according to the RAL color card. Commonly used are green welded mesh and black welded wire fabric. It also attracts customers for different application cases, such as fences, fences, partitions, decorative elements, etc.

Welded Wire Fabric VS Rebar

Rebar is known for its high tensile strength and is often used in heavy-duty structures such as industrial sites, underground parking lots, or other commercial buildings. The mesh of welded wire fabric has a more even strength distribution and is easier to handle, making it more suitable for light to moderate traffic areas such as driveways and sidewalks.

Quality Inspection

wire mesh for concrete

stainless steel welded wire for Sale

FAQ of Welded Wire Fabric

1. What Is The Material Of Welded Wire Fabric?

Wanzhi Steel uses high-quality carbon steel and galvanized steel to manufacture it. The wire mesh we produce has good corrosion resistance and can be used in various environments. It still performs well even when used in wet conditions.

2. Shapes and Sizes of It

Rectangular and square are common opening shapes of it. You can customize different sizes according to your actual needs. Send us specific data and we will give you quick feedback and a quote.

3. Is Welded Mesh Fabric Easy to Cut?

It is easy to cut and shape. So you can easily cut them using wire cutters. No matter where you want to lay it, stairs or wall panels, you can easily bend it to the desired size and lay it.

4. Where to Buy Welded Mesh Fabric From?

Wanzhi Steel is a famous steel manufacturer in China. Since we are capable of supplying quality steel products, including welded wire fabric, to customers all over the world. Thus, the staff of our factory has decades of production experience. Therefore, you don’t need to worry about the quality. During the production process, we will strictly control each process to ensure that the finished wire fabric has a flat surface and strong structure. If you are looking for this product for your project, welcome to Ask For An Online Quote!

WhatsApp: 8613938459717(Click To Chat)

Email: info03@wanzhisteel.com(Click To Email)

Leave Us A Message