Steel Grating Sheet Definition, Size, Price

As a multifunctional metal component in the industrial and infrastructure sectors, steel grating sheet, with its unique grid structure and reliable performance, plays a key role in load-bearing, protection, and drainage scenarios. Formed through a precise combination of load-bearing flat steel and crossbars, welded or press-locked, it combines exceptional load-bearing capacity with efficient drainage and ventilation. From operating platforms on factory floors to rainwater grates on municipal roads and decorative ceilings in shopping malls, steel grating, with its diverse material options and flexible customization, plays a vital role in a wide range of fields.

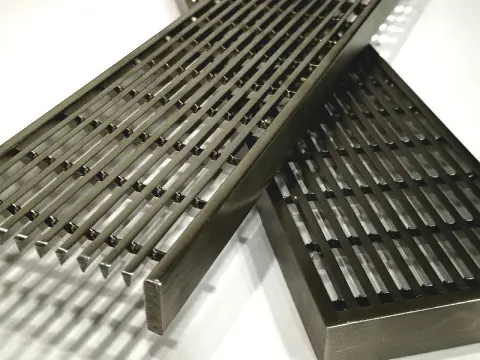

304 316 stainless steel floor drain Manufacturer

SS Steel Drain Grill Floor Grating

galvanised grating shipped to Czech Republic

Grating steel definition

Steel Grating Sheet (also known as steel grating, expanded metal grating, bar grating sheet, or grid plate) is a grid-like metal structure made of carbon steel or stainless steel. Its core structure consists of longitudinal load-bearing flat steel and transverse crossbars (twisted square, flat, or round steel) arranged at regular intervals and secured by welding, compression locking, splicing, or bolting. The surface can be galvanized to prevent rust. Its unique grid structure combines high strength with lightweight, airy, light-permeable, and slip-resistant properties. This plate-like product offers excellent load-bearing capacity and is widely used in industrial platforms, architectural decoration, and municipal transportation.

Steel Grating Sheet Material

Carbon Steel Grating

(1) Q235B plain carbon steel: The most economical basic material, offering excellent weldability but susceptible to corrosion. It must be hot-dip galvanized or painted, making it suitable for short-term projects or dry indoor environments.

(2) Q355B low-alloy steel: 30% stronger than Q235, offering a cost-effective, heavy-duty solution. Hot-dip galvanized steel is widely used in load-bearing applications such as industrial platforms and stair treads.

Galvanized Steel Grating

(1) Hot-dip galvanizing: The zinc layer is thick (30-275μm), providing a corrosion protection life of over 20 years. It is the standard choice for power plants and municipal projects, but welds require zinc supplementation.

(2) Electrogalvanizing: The zinc layer is thin (5-15μm), resulting in a smooth surface suitable for decorative purposes. It is recommended only for dry indoor environments and costs 30% less than hot-dip galvanizing.

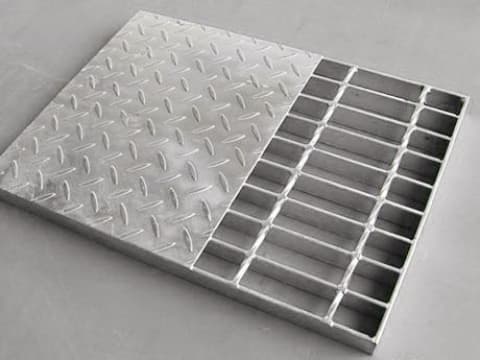

Outdoor 5mm thick heavy-duty trench cover

checker plate grating

Galvanized Steel Bar Grating

Stainless Steel Grating

(1) 304 stainless steel: A general-purpose corrosion-resistant material, resistant to weak acids and alkalis. It is suitable for food factories, shopping malls, and other locations. However, caution should be exercised in chloride ion environments (such as at the seaside).

(2) 316 stainless steel: Contains molybdenum and is resistant to seawater and salt spray corrosion, making it suitable for harsh environments such as coastal power plants and ship decks. Its cost is 40% higher than 304.

(2) 2205 duplex steel: Combines the corrosion resistance of 316 with a high strength of 550 MPa. It is specifically designed for use in sulfur-containing environments such as the petrochemical and chemical industries, but it is more expensive.

Aluminum Grating

Made of aluminum flat steel, and crossbars, it weighs only one-third of steel. The 6061-T6 grade offers sufficient strength and excellent weather resistance after anodizing, making it suitable for pedestrian bridges and decorative gratings.

Fiberglass Grating

It is insulating, acid- and alkali-resistant, and rust-resistant, but its load-bearing capacity is lower. It is mainly used in special environments such as substations and electroplating workshops.

Environmental Material Selection Guide

(1) Coastal/High Salt Fog Environments: 316L or 2205 Duplex Steel is preferred. Hot-dip galvanizing should be combined with a heavy-duty anti-corrosion coating.

(2) For strong acid environments: fiberglass or PP-coated gratings should be used; avoid metal.

(3) For Heavy Duty + Corrosion Resistance: 2205 Duplex Steel or hot-dip galvanized Q355B steel provides both strength and durability.

FRP Fiberglass Grating

Steel Grating Plate Heavy Duty

Non-slip Serrated Steel Grating for Walkway

Steel Grating Price

Steel grating prices can vary significantly depending on factors such as material, specification, manufacturing process, and quantity. The following is a detailed introduction:

Carbon Steel Grating

(1) Hot-Dip Galvanized Carbon Steel Grating: Usually, the price of hot-dip galvanized carbon steel grating is between $3 and $7 per piece, or $10 to $50 per piece for heavy-duty types. In terms of price per square meter, it is approximately $3.99 to $29.99 per square meter, and there are also some priced at $35.5 to $39.5 per square meter.

(2) Painted Carbon Steel Grating: The price of painted welded steel grating with a serrated surface is generally $10 to $500 per set.

Stainless Steel Grating

(1) 304/304L Stainless Steel Grating: The price of 304 stainless steel fence drainage channel serrated steel bar steel grating is $128 to $148 per square meter FOB.

(2) 316/316L Stainless Steel Grating: The price of stainless steel laser cutting grating of 304/316L is $80 to $380 per square meter.

Aluminum Grating

The price of aluminum steel grating is generally $15 to $30 per piece, and there are also some custom-made aluminum grid galvanized steel gratings priced at $15 to $200 per piece. There is also aluminum alloy material smooth grating used for catwalk stages, with a price of $8 to $10 per piece.

heel proof grating

aluminum grating

Green expanded grating

In addition, if you purchase in large quantities, the price will be more favorable. For example, when the purchase quantity of a certain platform floor galvanized steel grating reaches 400m², the FOB price can be reduced from $39.50 per square meter to $35.50 per square meter.

Steel grating Sheet Price Philippines

In the Philippines, the price of steel grating is influenced by various factors, including material, specifications, and quantity. Here’s a closer look:

Galvanized Steel Grating

(1) Heavy-duty press-lock steel grating with integral louvers costs between $14.30 and $22.40.

(2) Galvanized metal welded deck walkway grating costs between $17.99 and $21.99.

(3) Hot-dip galvanized, untreated press-lock steel driveway grating with serrated inserts costs between $5.00 and $13.20.

Stainless Steel Grating

304 & 316 stainless steel grating drain covers and serrated steel grating walkway decks generally cost between $18.60 and $25.80 per square meter.

Aluminum Grating

Based on the prevailing international market price range, aluminum grating typically costs between $15 and $30 per piece.

Factors Affecting Price

(1) Material: Carbon steel, galvanized steel, stainless steel.

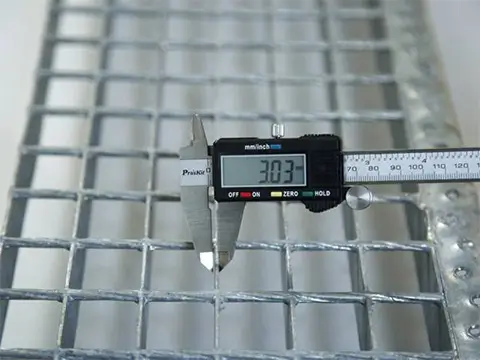

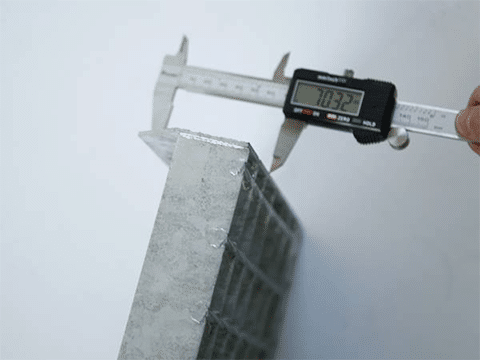

(2) Thickness: 3 mm, 5 mm, 10 mm, etc.

(3) Load Capacity: Industrial vs. light-duty.

(4) Supplier Quality: We recommend reputable, in-house manufacturers, rather than traders or middlemen.

For the most accurate quote, it’s best to consult with the supplier’s professionals.

Grooved grating drain cover

Round galvanized grating sheet

HDP Expanded Metal Grating

Steel grating size & thickness

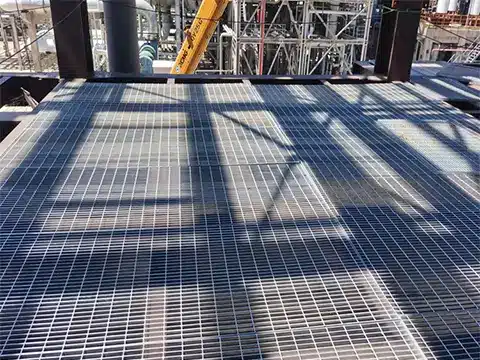

Industrial Platforms & Walkways

(1) 30×3/30×5 mm: Flat bars have a spacing of 30 mm and a thickness of 3 mm or 5 mm. They are used for light-duty walkways.

(2) 40×5 mm: Medium-duty, common general-purpose platforms.

(3) 50×5 mm: Heavy-duty platforms, such as those used in power plants and chemical plants.

Stair Treads

(1) 25×5 mm: High anti-slip requirements, dense mesh to prevent small objects from falling.

(2) 30×3 mm: Lightweight staircases.

(3) Width is typically 600mm to 1000mm.

Trench Grates

(1) 15×3 mm: Small drain outlet to prevent clogging.

(2) 20×5 mm: Municipal road drainage, load-bearing.

Architectural & Facades

(1) 10×2 mm: A refined appearance, suitable for curtain walls or guardrails.

(2) 20×3 mm: Provides ventilation and sunshade while also ensuring light transmission.

Offshore & Oil Rigs

(1) 50×6 mm: High load-bearing, corrosion-resistant, ISO 9001 certified.

(2) 60×8 mm: Extreme environments, such as helicopter decks.

For this application, hot-dip galvanizing (≥80μm) or an aluminum-magnesium coating is preferred.

Agricultural Use

(1) 30×3 mm: Animal enclosures and manure filters. Prevents hooves from getting stuck.

(2) 50×5 mm: Heavy machinery access.

Note: Use hot-dip galvanized grating to prevent rust and manure corrosion.

Selection Comparison Table

| Scene | Recommended grid size (mm) | Flat steel thickness (mm) | Material |

| Pedestrian bridge | 30×5 | 3-5 | Galvanized steel |

| Chemical plant platform | 40×5 | 5 | 316 stainless steel |

| Parking lot drainage ditch | 20×5 | 5 | Hot-dip galvanized |

| Decorative guardrail | 15×2 | 2 | Plastic-coated steel |

expanded metal floor grating

galvanized metal grating

Steel Grating Plate Uses

Steel grating weight

Calculation formula

Weight (kg/m²) = (Span between flat bars × Flat bar thickness × Flat bar width × Steel density (7.85) ÷ 1000) × (1 + 5-10%) × Weight gain factor.

Note: Flat bar dimensions are in mm.

Weight gain coefficient

(1) Galvanizing increases weight by approximately 3-5%.

(2) Serrated flat steel: Increases weight by 10-20% compared to plain flat steel.

Common Steel Grating Specifications and Weight Reference Table

| Grid size (mm) | Flat steel thickness (mm) | Theoretical weight (kg/m²) | Applicable Scenarios |

| 15×3 | 3 | 25~30 | Fine guttering, decking |

| 20×3 | 3 | 20~25 | Light walkways, stair treads |

| 30×3 | 3 | 15~20 | Industrial platforms, pedestrian bridges |

| 30×5 | 5 | 25~30 | Medium-load platforms |

| 40×5 | 5 | 30~35 | Heavy industrial areas, power plants |

| 50×5 | 5 | 35~40 | Truck access roads, oil platforms |

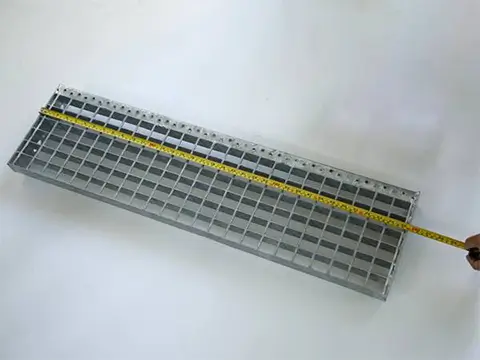

Thickness test of steel grating sheet

Thickness test of steel grating plate

Steel Grating Length Inspection

Weight Comparison of Steel Gratings of Different Materials

| Material | Density (g/cm³) | Weight Difference for Same Specifications |

| Carbon steel (Q235) | 7.85 | Baseline Weight |

| Stainless steel (304) | 7.93 | ~1% Heavier than Carbon Steel |

| Stainless steel (316) | 7.98 | ~1.5% Heavier than Carbon Steel |

| Aluminum alloy | 2.7 | 65% Lighter than Carbon Steel |

Key Factors Affecting Weight

(1) Flat bar spacing: The smaller the spacing, the heavier the weight (e.g., 15×3 is nearly twice as heavy as 30×3).

(2) Flat bar thickness: 5mm is approximately 40-50% heavier than 3mm.

(3) Crossbar density: The smaller the crossbar spacing (e.g., one crossbar every 50mm), the heavier the weight.

(4) Surface treatment: Galvanizing, plastic spraying, etc., can increase weight by 3-10%.

How to Quickly Estimate Weight?

(1) Light-duty grating (walkways, stairs): 15-25 kg/m².

(2) Medium-duty grating (industrial platforms): 25-35 kg/m².

(3) Heavy-duty grating (truck access): 35-50 kg/m².

304 Stainless Steel Serrated bar Floor Grating

Stainless steel grille welding

Carbon steel grating shipped to Chile

How to choose suitable steel grating sheets?

1. Clear purpose

It can be used for sunshade and ventilation of building exterior walls, interior partition ceiling walls, railings, protective grilles of vents, or grilles on gutter covers and platforms.

2. Select the material

Aluminum, galvanized steel, carbon steel, and stainless steel all offer durability and strong load-bearing properties, but their weight and corrosion resistance vary significantly. Aluminum has the lowest load-bearing capacity and can be used in non-load-bearing applications such as suspended ceilings and handrails. Besides metal, PVC/plastic wood grilles and glass/acrylic grilles are also suitable for balconies, bathrooms, and display shelves.

3. Determine size and clearance

Including gap size and thickness/strength, you can consult online technicians for help. The spacing of grilles for protection/ventilation purposes is different. If it is used as a sidewalk grille, choose a thicker material.

4. Environmental adaptability

Outdoor grilles need to be weather-resistant, such as aluminum alloy or stainless steel. In humid environments, avoid choosing rust-prone materials such as stainless steel, PVC or galvanized steel. In high-temperature environments, avoid plastics.

5. Installation and maintenance

Before purchasing, you should also clarify whether the installation is embedded, hanging, or ground-mounted, and reserve installation space. In terms of post-maintenance, metal grilles require rust prevention treatment, while PVC or aluminum grilles are relatively simple to maintain.

6. Budget

If you want to reduce costs, we recommend: PVC, ordinary carbon steel. If you want high cost performance, we recommend aluminum alloy, galvanized steel, and stainless steel.

galvanized walkway grating

Swage-Locked Stainless Steel Grating Platform

The structure of welded grating

Common Application Recommendations

| Applications | Recommended Materials | Recommended Clearance |

| Architectural shading | Aluminum alloy, steel | 5-15cm (for sunshade efficiency) |

| Interior partitions | Wood, PVC | 2-10cm (for aesthetics) |

| Industrial platforms | Galvanized steel, fiberglass | ≤3cm (for fall protection) |

| Garden fencing | Plastic-wood, cast iron | ≤10cm (for pet escape prevention) |

Steel Grating Sheet manufacturer– Wanzhi Steel

In summary, steel grating, with its high strength and adaptability, has become a practical component in industries such as industry, municipal administration, and construction. Whether meeting the standardized requirements of common scenarios or the customized requirements of specialized environments, its value is maximized through flexible adjustments in materials and specifications. As a professional steel grating manufacturer, we always prioritize product quality and offer HDP carbon steel, SS steel, and special-shaped gratings, balancing cost-effectiveness, quality control, and installation guidance to help you efficiently meet various grating application needs.

Galvanized steel grille door mat

steel grating for sale

metal grating floor sheet shipped to Colombia

Why Choose Wanzhi Steel?

(1) Mechanical facilities: Fully automated press welding equipment and CNC punching machines, along with two hot-dip galvanizing lines, support various processes, including press welding, splicing, and serrated anti-skid coating.

(2) Price Competitiveness: Large orders receive additional discounts, effectively reducing procurement costs. We also offer a variety of material options to meet diverse budgets.

(3) Stable Delivery: Regular order production takes 7-15 days, with immediate production scheduling upon order placement. Prompt delivery ensures your project is completed on schedule.

(4) Strict Quality Inspection: Each batch undergoes load and dimensional testing to ensure compliance with standards such as EN ISO 14122. We also meet ASTM/GB/ISO standard.

(5) Flexible Customization: We support custom production for non-standard sizes, custom cuts, and special apertures. We offer a variety of surface finishes, including plastic spraying, electroplating, and anti-slip graining, as well as brand logo embossing.

or send an email to:info03@wanzhisteel.com

Wanzhi Steel is an ISO 9001-certified steel factory located in Hebei, China. It has been specializing in the production of Steel Grating Sheet, Galvanized expanded metal lath, Expanded Metal Grating, Stainless steel grating, and Galvanized Grating for 14 years, with a monthly output of 1,800 tons. With high-quality products and good services, its products have been exported to more than 120 countries around the world.

Leave Us A Message