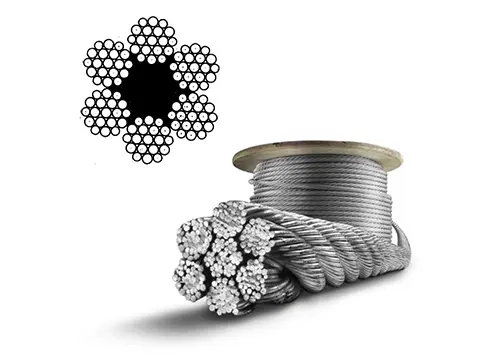

Stainless Wire Rope

Stainless Wire Rope, also called stainless steel cable or stainless steel rope cable, is a high-strength rope made of multiple strands of stainless steel wire. It is widely used in industry, construction, marine, aerospace, and other fields. With its excellent corrosion resistance, high strength, and long-term durability, it has become the preferred material in many critical applications. Commonly used are 3 16 steel cable, 1 4 steel cable, 1 8 stainless steel cable, 1 16 stainless cable, 1 4 stainless steel cable. Wanzhi Steel is a high-quality stainless steel rope & cable supplier and manufacturer in China. We produce 304/304L/316/316L/201 high-quality stainless steel ropes with all diameters and structures. You can find all sizes suitable for your project here.

1 4 stainless steel cable

stainless wire rope

Steel Cable Rope

Stainless Wire Rope Specification

| Item | Stainless wire rope |

| Place of Origin | Hebei, China |

| Standard | AISI, ASTM, BS, DIN, JIS, GB, EN |

| Grade | 304, 304l, 316, 316l stainless steel |

| Coil weight | 50-1000KG |

| Delivery Time | 8-14 days |

| Structure | 1*7,1*19,1*37,6*19,6*37,7*19, 7*7, FC/PP/WSC/IWRC Core |

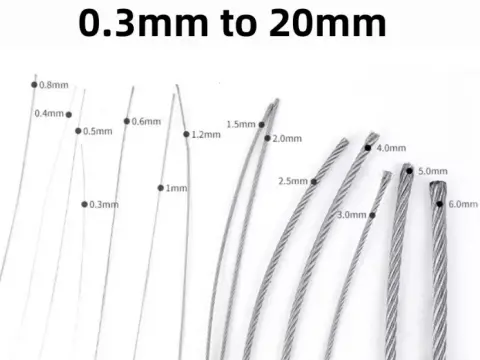

| Diameter | 0.5mm-32mm |

| Color | Custom available |

| Lay | Left hand regular lay or right hand regular lay |

| Usage | Cable seal, aircraft cable, etc. |

| Surface treatment | Highly Polished |

| Surface coating | No coating, or PVC PE PP PU, Vinyl optional |

| Tensile strength | 1570MPA, 1670MPA, 1770MPA, 1870MPA, 1960MPA |

| Sample | Free Available |

| Payment term | TT 30% Advance + 70% Balance |

| Price Item | FOB, CIF, EXW, CFR, etc |

| Packing | 500m/reel, 1000m/reel, 2000m/reel |

| Certification | ISO 9001, SGS, ABS, BV |

| MOQ | 5 tons |

| Transportation | By sea, by land |

What is Stainless Wire Rope?

Stainless steel wire rope, as the name implies, is a wire rope made of stainless steel. Stainless steel is an alloy steel that mainly contains elements such as chromium (Cr) and nickel (Ni), which give it excellent corrosion resistance and oxidation resistance. Stainless steel wire rope is made by twisting multiple strands of stainless steel wire in a specific way to form a rope with high strength, high flexibility, and good wear resistance. It can maintain stable performance in various harsh environments, so it is widely used in many industries.

Metal rope net

high tensile stainless steel wire rope

Type 316 Stainless Steel Cable

Common structures

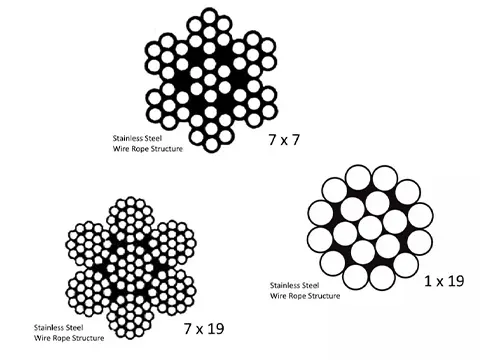

The structure of stainless steel wire rope is usually made of multiple strands of steel wires. Common structures include:

1) 1×7 structure: composed of 1 center wire and 6 outer wires, suitable for light load scenarios.

2) 1×19 structure: composed of 1 center wire and 18 outer wires, with higher strength and rigidity.

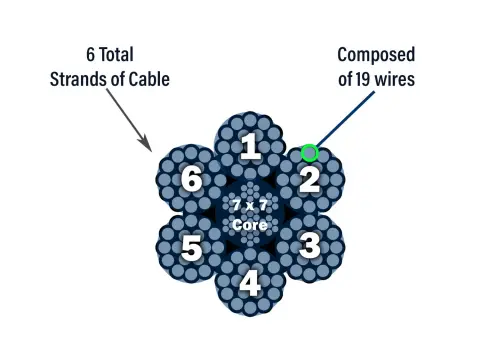

3) 7×7 structure: composed of 7 strands of steel wire rope, each strand is twisted with 7 steel wires, suitable for medium loads.

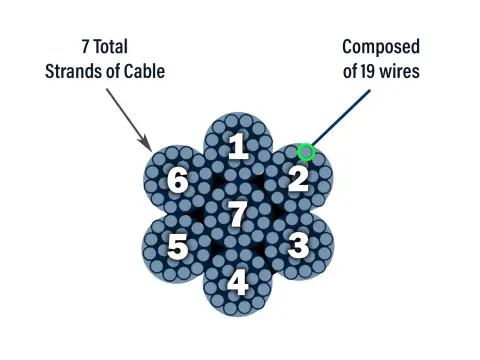

4) 7×19 structure: composed of 7 strands of steel wire rope, each strand is twisted with 19 steel wires, with higher flexibility and fatigue resistance.

Advantages of stainless steel wire rope

1. Strong corrosion resistance: Stainless steel material gives the wire rope excellent corrosion resistance, and can maintain stable performance for a long time in humid and corrosive environments.

2. High strength: Through the precise twisting process, the ss wire rope can withstand large tension and is suitable for heavy loads and occasions requiring a high safety factor.

3. Good flexibility and wear resistance: stainless steel wire cable has good flexibility and wear resistance, and can adapt to various complex bending and twisting movements while maintaining a long service life.

4. High dimensional accuracy: The dimensional accuracy of stainless steel cable rope can reach ±0.01mm, ensuring its reliable application in various precision equipment.

5. Safety: High strength and high reliability make it a safe choice in critical applications, such as lifting equipment and bridge cables.

6. Versatility: The structure and specifications of a stainless steel cable are diverse, which can meet the needs of different scenarios.

7. Aesthetics: The surface of stainless steel is smooth and has a metallic luster, which is suitable for occasions with high requirements for appearance.

7-x-19-cable-construction-graphic

6-x-19-Cable-Construction-graphic

stainless steel deck cable 3 16 steel cable

Uses

Stainless steel wire rope is important in many fields due to its excellent performance. Here are some of the main application scenarios:

1. Coal, petroleum, metallurgy: used for hoisting, traction, fixing, and other occasions, subject to huge tension and wear.

2. Chemical, fertilizer, chemical fiber: connectors, lifting rings, etc., to ensure the safe operation of the equipment.

3. Ship, bridge, electricity: cables, slings, etc., subject to huge tension and vibration.

4. Tourism, water conservancy, and light industry: used for amusement facilities, water conservancy facilities, light industrial equipment, and other occasions.

5. Safety protection fields: such as anti-fall nets, stainless steel rope nets, etc., provide strong protection for people’s lives and property safety.

6. Architecture: support and fixation of glass curtain walls of high-rise buildings.

7. Aerospace: used for aircraft control cables, requiring high strength and fatigue resistance. Used for the support and adjustment of satellite antennas.

8. Daily life: stainless steel chandeliers, decorative structures such as stair handrails and guardrails, climbing ropes, bungee ropes,s and other sports equipment.

wire cable railing

Architectural Cable Safety Mesh

crimping vinyl coated wire rope

What are the types of Stainless Wire Rope?

Stainless steel wire rope can be divided into many types according to structure and material. The following are 3 main classification methods:

Ⅰ. Classification by material

1. 201 stainless steel wire rope: has good corrosion resistance, heat resistance, and low-temperature strength, but its corrosion resistance is slightly weaker than 304 and 316 materials.

2. 304 stainless steel wire rope: the most common austenitic stainless steel, with good corrosion resistance, heat resistance, and low temperature strength, widely used in food and medical equipment.

3. 316 stainless steel wire rope: Molybdenum (Mo) is added to 304 to improve the resistance to pitting and crevice corrosion. It is the noblest among stainless steels and is suitable for marine environments and chemical industries.

Here is an article that comprehensively describes the differences between 316 and 304 stainless steel for your reference.

Ⅱ. Classification by structure

1. Single-strand structure: such as 1×3, 1×7, 1×19, etc., suitable for light loads and occasions requiring higher flexibility.

2. Multi-strand structure: such as 7×7 (6×7+WSC), 7×19 (6×19+WSC), 6×37, etc., suitable for heavy loads and occasions requiring higher wear resistance.

Ⅲ. Classification by contact form

1. Point contact: The adjacent layers of steel wires in a strand are in point contact, the structure is relatively loose, and it is suitable for light loads.

2. Line contact: The adjacent layers of steel wires in a strand are in line contact, the structure is tighter, and it is suitable for medium and heavy loads.

3. Surface contact: The adjacent layers of steel wires in a strand are in surface contact, which has higher strength and wear resistance, and is suitable for heavy loads.

steel cable structure

metal cable

Wire rope production line

Manufacturing process of stainless steel wire rope

The manufacturing of stainless steel cables in each steel plant follows the following steps:

Select high-quality stainless steel that meets the standards → Drawing through a wire drawing machine → Twisting into strands → Twisting into ropes (note the direction is left-hand or right-hand twist, control the twist length) → Heat treatment → Surface polishing or coating treatment → Mechanical properties test and appearance inspection → Standard packaging

Specific steps

1. Raw Material Preparation: Select standard stainless steel wire rod, such as 304 or 316 stainless steel wire rod, and pickle and anneal it.

2. Wire Drawing: The wire rod is drawn through drawing dies of varying apertures, gradually reaching the desired diameter while lubricating and cooling the wire rod to prevent heat damage.

3. Stranding: Multiple stainless steel wires are twisted into strands (common strand structures include 1×7 and 1×19) using a stranding machine according to a predetermined lay direction (left-hand or right-hand lay) and lay pitch.

4. Roping: Multiple strands (usually 6 strands + 1 fiber or steel core) are wound onto a central core (fiber or steel core) using a rope closing machine according to the specified lay direction and lay pitch, forming a complete stainless steel wire rope.

5. Heat Treatment: The rope undergoes a stabilization heat treatment, such as low-temperature tempering, to eliminate internal stresses and enhance overall strength and toughness. 6. Surface Treatment: Common treatments include electropolishing to improve surface finish and corrosion resistance, passivation to form an oxide film for enhanced rust resistance, and PVC coating to further enhance protection.

7. Inspection & Cutting: Qualified products are screened through visual inspection for broken wires and deformation, dimensional measurements such as diameter and lay length, and mechanical property tests such as tensile strength and breaking strength. Finally, products are cut to specified lengths as required.

Stainless steel wire rope production line

Stainless Steel Wire Rope Manufacturer

High Tension Stainless Steel Wire Rope

Maintenance and care of stainless steel wire rope

Although stainless steel rope has excellent corrosion resistance, it still needs regular maintenance in some extreme environments:

1. Regular inspection: Check the surface of the wire rope for wear, broken wires, or corrosion.

2. Cleaning: Clean and wipe the surface with clean water or neutral detergent, avoid using acidic or alkaline detergents.

3. Lubrication: Lubricate the wire rope to reduce friction and wear.

4. Replacement: When the wire rope is broken, it should be replaced in time to ensure safety.

Stainless steel wire rope price

The price of stainless steel wire rope varies by region, supplier, and market conditions.

I. Price range

The following is a reference price range based on international markets (such as the US, European, or Asian markets) for your reference:

1. 304 stainless steel wire rope

Diameter 1mm: about 1.5-3 US dollars/meter

Diameter 3mm: about 4-7 US dollars/meter

Diameter 5mm: about 8-15 US dollars/meter

Diameter 10mm: about 30-45 US dollars/meter

2. 316 stainless steel wire rope

Diameter 1mm: about 2-4 US dollars/meter

Diameter 3mm: about 6-10 US dollars/meter

Diameter 5mm: about 12-18 US dollars/meter

Diameter 10mm: about 35-60 US dollars/meter

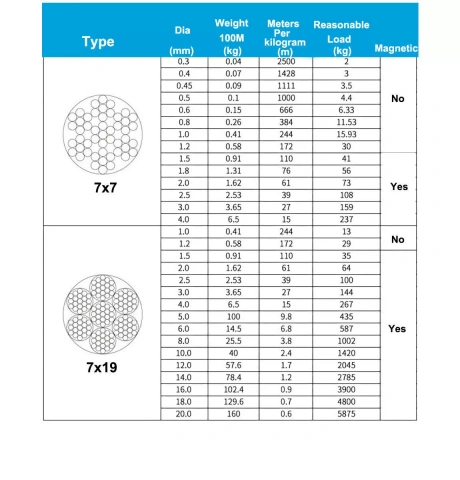

Rope diameter comparison table

3. Special structure or treatment

The price of wire rope with 7×19 structure is about 20%-50% higher than that of 1×7 structure.

The price of PVC coated wire rope is about 30%-100% higher than that of ordinary wire rope.

Ⅱ. Factors affecting the price

1. Raw material cost: Fluctuations in the prices of metals such as nickel and chromium in the international market will directly affect the price of stainless steel wire rope.

2. Transportation cost: Transportation costs (such as sea or air transportation) will increase the total cost.

3. Tariffs and taxes: Import tariffs and taxes in different countries will affect the final price.

4. Supplier brand: Products from well-known brands are usually more expensive. It is recommended that you choose high-quality suppliers with quality assurance, and you don’t have to pursue brands blindly.

Ⅲ. How to get an accurate quotation

1. Provide detailed information

Including diameter, length, structure, surface treatment, etc., so that suppliers can provide accurate quotations.

2. Bulk purchases

Ask for bulk discounts or long-term cooperation prices.

3. Compare quotations

Get quotations from multiple suppliers and choose the most cost-effective option. It is recommended not to blindly pursue low prices, which means that the quality may not meet the standards.

Wire rope structure weight comparison table

Stainless Steel Cable Manufacturer – Wanzhi Steel

Stainless steel wire rope offers exceptional performance, corrosion resistance, high strength, and the ability to easily withstand harsh environments, ensuring a long service life. With the rapid development of industries like industry and construction, demand for stainless steel wire rope continues to rise, creating a promising market. Choosing stainless steel wire rope not only offers competitive advantages but also promises substantial profits, making it a wise choice!

price of steel cable

steel cable manufacturer

steel cable suppliers

Why Choose Us?

1. One-Stop Response: Full production chain from raw materials to finished product. Selected high-quality stainless steel, such as 304/316, undergoes precision drawing and heat treatment to ensure superior corrosion resistance.

2. Advanced Technology: Intelligent CNC equipment twists and binds the strands, precisely controlling parameters to ensure a tight structure and uniform stress distribution, ensuring excellent fatigue resistance.

3. Quality Inspection: Equipped with specialized equipment such as spectrometers and tensile testing machines, we conduct comprehensive testing of composition, strength, and corrosion resistance.

4. Customization: Wanzhi Steel offers a variety of structures, specifications, and surface finishes to meet diverse application scenarios. We can quickly respond to non-standard customization.

5. Extensive Export Experience: We are well-versed in international standards and export procedures, providing professional packaging and complete certification. We ensure prompt delivery and immediate production scheduling upon order placement.

Wanzhi Steel is an ISO 9001-certified steel factory located in Hebei, China. It has been specializing in the production of SS wire rope mesh, cyclone mesh, perforated stainless steel sheets, Vinyl Coated Chain Link Fence, Stainless Steel Handrail Cable, and Stainless Steel Cable, with a monthly output of 1,800 tons. With high-quality products and good services, its products have been exported to more than 120 countries around the world.

Leave Us A Message