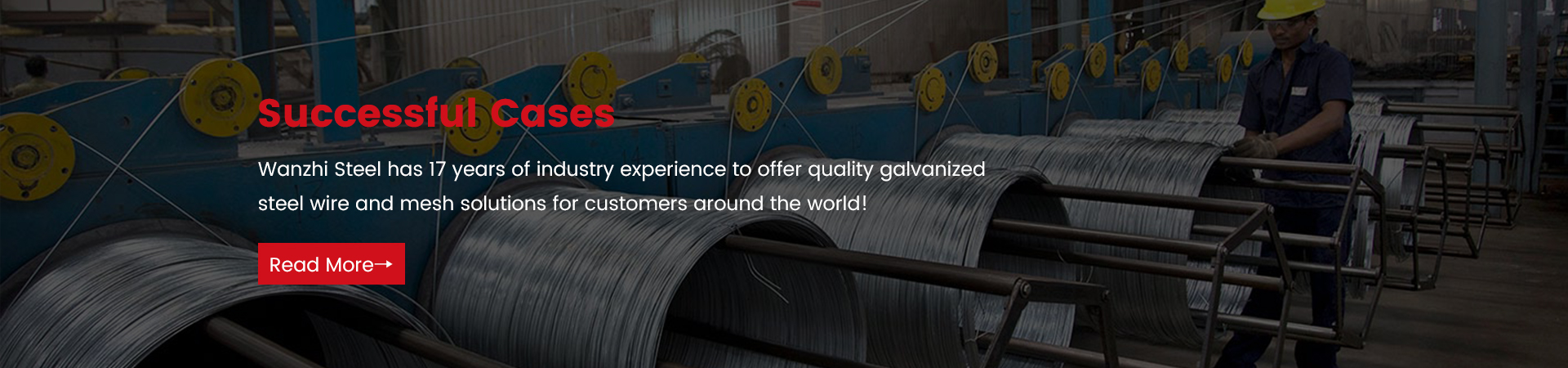

Perforated Aluminum and Galvanized Perforated Sheets Shipped to Hungary

Wanzhi Steel‘s 1,370 perforated metal sheets arrived in Hungary on time last week. The customer is very satisfied with the cooperation and hopes to establish a long-term partnership. The following is a detailed record of this cooperation.

Prepare for shipment

Loading into container

Loading into container

Customer Background

Local supplier, Mediaker Kft, a major building materials distributor in Budapest, was seeking to import competitively priced perforated metal sheets from China for local construction and manufacturing clients. Their client base includes architectural design institutes, construction companies, and real estate developers. The materials were primarily intended for exterior wall decoration and interior partition projects. The client, referred to us directly by a Romanian customer, placed an order for 1,370 sheets of perforated metal mesh, comprising two types of sheet materials, based on their established trust in us.

Order details

| Parameters | Perforated aluminum sheet | Perforated galvanized sheet |

| Material | 5052/H24 | DX51D + Z galvanized steel |

| Thickness | 1.5mm | 1.2mm |

| Width | 1000mm | 1000mm |

| Length | 2000mm | 2000mm |

| Aperture | 3mm (round hole) | 4mm (round hole) |

| Pitch | 6mm (center distance) | 8mm (center distance) |

| Porosity | ~20% | ~15% |

| Surface Treatment | Anodized | Zinc coating (Z80, 80g/m² on both sides) |

| Packing | Wooden box + moisture-proof paper | Wooden box + anti-rust film |

| Order Quantity | 550 sheets | 820 sheets |

| Delivery Time | 25 days | 30 days |

5052 aluminum plate

DX51D+Z80 Hot dipped galvanized steel sheet

No burrs on edges and surfaces

Production Process

(1) Raw Material Procurement: We rigorously select high-quality aluminum and galvanized sheet materials to ensure their composition and performance meet international standards and order specifications.

(2) Sheet Cutting: We utilize high-precision CNC cutting equipment to cut sheets to the desired width and length.

(3) Piercing: We utilize high-precision CNC punching machines to automatically determine the hole diameter, spacing, and pattern, while the equipment automatically monitors perforation quality.

(4) Surface Treatment: We anodize the perforated aluminum sheet; we clean and inspect the surface of the perforated galvanized sheet to ensure the integrity of the zinc coating.

Quality Inspection

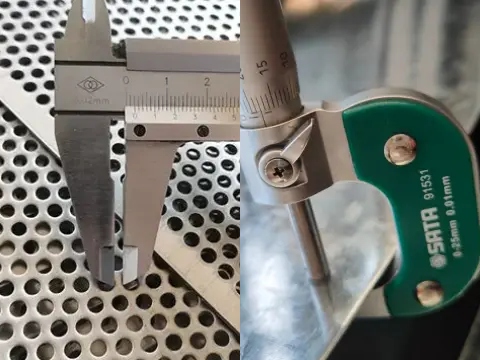

(1) Dimensional Inspection: Each batch of perforated metal sheets is inspected for dimensional parameters such as thickness, width, length, hole diameter, and hole spacing.

(2) Appearance Inspection: The surface of the sheet is inspected for defects such as scratches, dents, deformation, and rust, and the hole edges are checked for smoothness and burr-free.

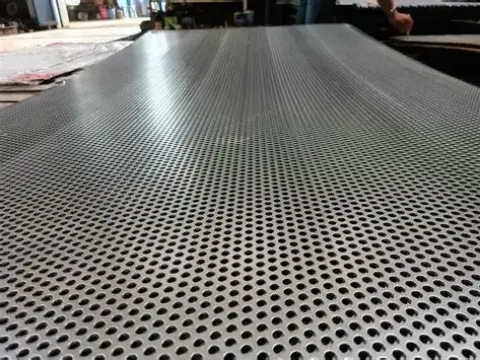

5052 aluminum perforated plate

Wanzhi Steel perforation production line

Thickness and hole distance detection

(3) Performance Testing: Aluminum sheets are tested for hardness and corrosion resistance, and galvanized sheets for zinc adhesion and salt spray resistance.

(4) Qualification Verification: Products that meet all requirements after the above tests are deemed qualified and allowed to proceed to the next stage. Unqualified products are reworked or scrapped.

Packaging and delivery

(1) Aluminum Sheet: Each 10 sheets is separated by moisture-proof paper and packed in reinforced wooden boxes to prevent deformation during transport.

(2) Galvanized Sheet: Each 10 sheets is wrapped in anti-rust film and packed in wooden boxes with foam cushioning to prevent scratches on the zinc coating.

(3) Logistics: Shipped by sea to the Port of Budapest, Hungary (FOB Qingdao, arrival time 30 days).

Perforated galvanized steel sheet

Standard export packaging

Wooden pallet fixing

Mechanical parameter comparison

| Performance | Perforated Aluminum Sheet (5052-H24) | Perforated Galvanized Sheet (DX51D+Z) | Standard cold-rolled steel plate |

| Density (g/cm³) | 2.68 | 7.85 | 7.85 |

| Tensile Strength (MPa) | 210-260 (H24) | 270-420 | 270-420 |

| Corrosion Resistance | Excellent (Marine Grade Corrosion Resistance) | Excellent (Galvanized layer is rust-resistant) | Poor (requires painting) |

| Weight (1㎡, 1.5mm) | 4.02kg | 11.78kg | 11.78 kg |

| Applicable Environment | Interior/Marine/Curtain Wall | Outdoor/Industrial/Architectural | General structural use |

Tip: If higher strength is required, you can choose 6061-T6 aluminum plate (tensile strength ≥310MPa) or S350GD+Z galvanized steel (tensile strength ≥350MPa).

oval perforated aluminum sheet

perforated metal fence

Indoor ceiling

Customer Feedback

The hole pattern is precise, and installation is easy. The galvanized sheet has excellent rust resistance and meets the salt spray test standards. The packaging is secure and there is no damage during transportation. I am very satisfied and look forward to long-term cooperation!” – Metalker Kft

Advantages of Perforated Metal Sheet

Advantages of Perforated GI Plate

(1) High Strength: Resists pressure and impact, making it suitable for load-bearing structures (such as industrial platforms and guardrails).

(2) Superior Rust Resistance: Protected by a galvanized coating, it remains rust-free for 10-15 years of outdoor use.

(3) High Cost-Effective: Lower in price than stainless steel, yet more durable than ordinary steel.

Advantages of Perforated Aluminum Plate

(1) Lightweight: Weighs only 1/3 of galvanized sheet, saving transportation and installation costs.

(2) Corrosion-resistant: Naturally resistant to oxidation, suitable for humid, acidic, and alkaline environments (such as curtain walls and ships).

(3) Elegant and easy to process: Anodized and colorable, offering flexible styling options (for enhanced decorative effects).

If you also need perforated metal sheet, please contact Wanzhi Steel.

Consult Now:

Official website: https://wanzhifence.com

Email: info03@wanzhisteel.com

Our WhatsApp: 8613938459717

Leave Us A Message