Oval Wire

The oval wire is a high-strength steel wire with an oval cross-section. Compared with round steel wire, it has unique advantages, such as increased structural stability and improved stress distribution. Therefore, it is widely used in fence wires for large livestock such as cattle and horses in agriculture and support frames in planting. Wanzhi Steel stocks a large number of commonly used specifications of galvanized oval wires and PVC coated oval wires. The sizes can be customized. Welcome to contact us.

Oval wire for agricultural use high tensile

Wire section shape – oval

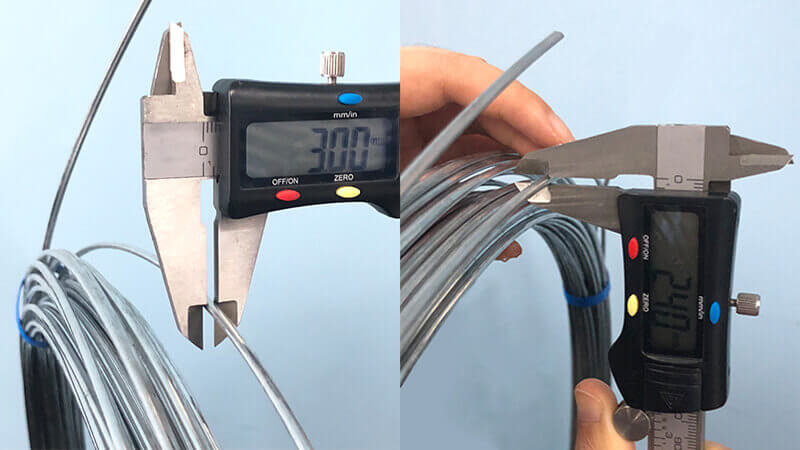

Fast Delivery 3.0×2.4Mm Galvanized Oval Wire

Oval Wire Specification

| Item | Oval wire |

| Place of Origin | Hebei, China |

| Material | Carbon Steel, Medium/High Carbon Steel |

| Tensile Strength | 300-1500N/m2 |

| Steel Grade | Q195, Q235, 45#,55# , 60#, 70# |

| Delivery Time | 15-21 days |

| Color | Silver |

| Surface | Galvanised Zinc |

| Zinc coating | 30-275g/m2(Z30-Z275) |

| Wire diameter | 2.0*2.4mm /2.2*2.7mm/2.4*3.0mm, 17/15/16/14/12 |

| Length | 100-1000m/roll |

| Coil weight | 25 kg, 45 kg |

| Application | Fencing, agriculture, cattle fence, Binding wire, Construction wire mesh manufacturing |

| Packing | plastic film and woven bag |

| Certificate | BSCI, TUV, ISO, etc |

| MOQ | 3 Tons |

| Payment Term | T/T, (30%+70%) |

What is oval wire?

It is a high-tensile steel wire with a silvery-white surface and galvanized. Therefore, it can also be called Galvanized Oval Wire. The cross-section is oval. Compared with round steel wire of the same diameter, oval steel wire is stronger, harder, and more fatigue-resistant. It is also easier to handle and operate than round steel wire. In addition to low carbon steel, it can also be made of high-carbon steel, making it an ideal choice for many projects, especially for many uses in Uruguay and Paraguay.

Tie Wire – Flat Wire, Round Wire

Cut view dimensions (mm)

gi oval wire

Advantages

1. Higher Tensile Strength

For the same cross-sectional area, the oval shape provides higher mechanical strength and deformation resistance than round wire.

2. Flexibility and Fatigue Resistance

The oval shape makes it easier to bend in specific directions, resulting in better toughness and resistance to repeated bending, making it less likely to break.

3. Space and Material Savings

The flat shape allows for a tighter structure when woven or layered, reducing material usage and achieving greater space efficiency.

4. Larger Contact Area

Compared to round wire, the surface area of the oval wire is larger, providing greater adhesion and wrapping.

5. Unique Filtration Performance

When used in screens, the gaps formed by the oval wire are more uniform and less likely to clog. The oval structure also better absorbs vibration and energy, contributing to noise reduction.

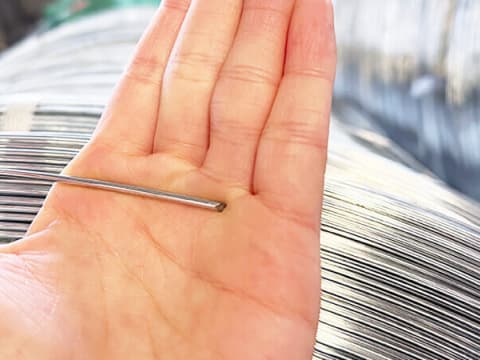

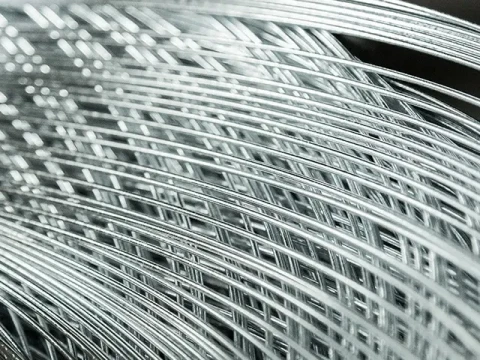

Fine wire coils stock

difference size in stock

inner package

Oval wire of different materials

1. High Carbon Steel Wire: Offers exceptional strength and wear resistance.

2. Stainless Steel Wire: Offers excellent corrosion and rust resistance.

3. Spring Steel Wire: Features a high elastic limit and excellent relaxation resistance, allowing it to withstand frequent, repeated bending and deformation without breaking.

4. Alloy Steel Wire: By adding alloying elements to carbon steel, it achieves higher hardenability, strength, and wear resistance.

5. Galvanized Steel Wire: Galvanized steel wire provides excellent rust protection at a low cost.

6. Brass Wire: Offers excellent electrical and thermal conductivity, corrosion resistance, and is easy to process.

7. Phosphor Bronze Wire: Offers higher strength, elasticity, and wear resistance than brass, and also offers excellent fatigue and corrosion resistance.

Galvanized flat oval wire diameter measurement

Galvanzied Oval Wire Case

Application

1. Filtration and Screening

Used in vibrating screens in the oil and mining industries, dewatering and de-mediation screens in coal washing, and precision filtration in the food and pharmaceutical industries.

2. Reinforced Products

Used in the rubber industry as a skeletal material for radial tires and conveyor belts, and as a fiber additive in concrete, it provides excellent impact and fatigue resistance, as well as enhanced grip.

4. Industrial

Used in the spring manufacturing industry for the manufacture of mechanical springs to meet specific requirements. Other applications include brush wires, sealing components, and more.

5. Hardware and Mesh

Used in high-end weaving applications such as decorative netting and protective netting, as well as in tying wire and clamps. Its shape provides increased binding strength and resistance to loosening.

For agricultural fence wire

Trellis wire structural support

Hinged Sheep Pasture Fence

Recommended uses for different materials

1. High Carbon Steel Wire: A cost-effective option for manufacturing parts requiring high fatigue resistance, such as heavy screens and springs. 2. Stainless Steel Wire: Ideal for harsh, wet, and corrosive environments such as food, chemical, and marine environments.

3. Spring Steel Wire: Ideal for high-performance springs.

4. Alloy Steel Wire: Commonly used for heavy machinery components with specific performance requirements.

5. Galvanized Steel Wire: Commonly used for standard screens or fencing in outdoor environments.

6. Brass Wire: Commonly used in electronics, decorative applications, and specialized applications requiring magnetic shielding.

7. Phosphor Bronze Wire: Commonly used for high-grade elastic components such as diaphragms and electrical contacts.

Price

Its price is mainly determined by the material grade, zinc layer, diameter, and purchase volume.

Price reference

1. Ordinary galvanized: 0.21~0.42 USD/meter Single-strand oval core wire, basic rust prevention.

2. Thickened hot-dip galvanized: 0.42~0.83 USD/meter Zinc layer ≥60μm, high corrosion resistance.

3. PVC coated: 0.56~1.11 USD/meter. Optional colors (green/black), stronger weather resistance.

4. Military/prison grade: 1.11~2.08 USD/meter High-strength core wire + dense barb spacing.

To get a quote today, you can always contact our Friendly professional technicians!

3.0*2.4Mm Galvanized Steel Oval Wire

surface of Oval-Wire

14 gauge galvanized wire surface

How is oval wire made?

The production process of elliptical steel wire usually includes the following steps:

1. Raw material selection: Select high-quality steel wire rods as raw material.

2. Drawing and forming: The steel is drawn into an elliptical cross-section by a drawing machine.

3. Heat treatment: The drawn elliptical steel wire is heat treated to improve its strength and toughness.

4. Surface treatment: The surface is galvanized and optionally coated to improve its corrosion resistance and aesthetics.To form high tensile galvanized steel wire.

5. Cutting: After rolling, it is cut into the required weight according to needs and packaged in the standard way, with plastic inside and braid outside.

Galvanized Metal Wire Cutting-Packaging

Quality Check

Tensile strength test

40 60 90 Salt Spray Tester

Our package

Common sizes and roll weights

| Size | Specification | Breaking Force | Zinc Coating | Length | Weight |

| 17/15 | 3.0*2.4mm | 700kgf | 35-180g/m2 | 1000m | 43.5kg |

| 16/14 | 2.7*2.2mm | 700kgf | 35-180g/m2 | 1000m | 37kg |

| 16/14 | 2.7*2.2mm | 600kgf | 35-80g/m2 | 1250m | 45kg |

| 15/13 | 2.4*2.0mm | 500kgf | 35-80g/m2 | 1500m | 45kg |

| 14/12 | 2.2*1.8mm | 400kgf | 35-80g/m2 | 1900m | 45kg |

| Nº12 | 2.4*2.8mm | 500Mpa | 35-80g/m2 | 465m | 25kg |

| Nº6 | 4.55*5.25mm | 500Mpa | 35-80g/m2 | 170m | 25kg |

Oval Wire for Fence Wholesale

With unlimited production capacity and patient and friendly professionals, we provide online quotes to ensure on-time shipment every time. Whether you need a sample order or wholesale quantity. You can always consult qualified professionals when choosing the best elliptical wire specifications and sizes.

Get samples or a bulk quote! Chat with Us Online,

or send an email to: info03@wanzhisteel.com.

Wanzhi Steel Factory is an ISO 9001 certified enterprise located in Hebei, China. Specializing in the production of stainless steel wire, PVC/Vinyl/PE coated iron wire, electro GI Wire, annealed wire, straight cut wire, binding wire, Zinc Aluminum Alloy Wire, Galfan Wire, and low carbon steel wire, with high-quality products and good services, the products have been exported to more than 120 countries around the world.

Leave Us A Message