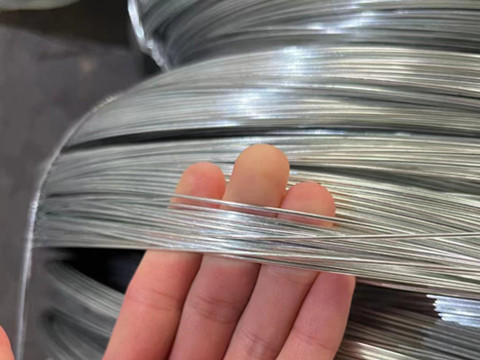

12 Gauge Galvanized Wire

12-gauge galvanized steel wire is an economical and practical steel wire commonly used in industry, agriculture, and construction. With standard specifications, it’s commonly used for lashing, securing, and bundling. It’s rust-resistant, offers moderate strength, and good toughness. As a manufacturer, Wanzhi Steel offer a variety of electroplated and hot-dip options, supporting both custom and bulk exports, making us a reliable and cost-effective supply chain choice.

Zinc coated Wire for bundling

12 Galvanized Wire For Sale

Hot Dipped Galvanized Wire

Specification

| Item | 12 Gaguge Galvanized wire(12 Ga GI Wire) |

| Place of Origin | Hebei, China |

| Standard | AISI, ASTM, BS, DIN, JIS, GB, EN |

| Material | Q195/Q235/SAE1006/SAE1008 |

| Delivery Time | 8-14 days |

| Surface Treatment | Electro galvanizing, Hot-dip galvanizing |

| Zinc Coating | Cold-Dip: 40-60g/㎡, Hot-Dip:100-200g/㎡ |

| Diameter | 2.77mm |

| Coil Weight | 1 kg – 500 kg |

| Intensity Level(MPa) | 800-1200 |

| Tensile strength | 300N/ sqm-550N/ sqm |

| Type | Single-loop/double-loop tying wire, U-shaped tying wire, straight-cut |

| Usage | Gabion, wire mesh, fence, building construction |

| Sample | Free Available |

| Payment term | TT 30% Advance + 70% Balance |

| Price Item | FOB, CIF, EXW, CFR, etc |

| Packing | Standard export packaging |

| Certification | ISO 9001, SGS, ABS, BV |

| MOQ | 10 tons |

| Transportation | By sea, by land |

Definition

12-gauge galvanized wire is iron wire with a diameter of approximately 2.77 mm (based on Birmingham Wire Gauge (BWG) or Standard Wire Gauge (SWG)). It is made from Q195/Q235 low-carbon steel wire that is drawn and then galvanized. Galvanizing is a rust-proof process that can be done by either electroplating or hot-dip galvanizing. Its strength and flexibility make it suitable for direct use, mechanical winding, or secondary processing.

Electro Galvanized Wire for Sale

Electro Galvanized Steel Wire

Finished Galvanized Wire

Core Features

1) Universal and Easy to Fit

2.77mm (10-Gauge AWG) is a common international specification, making it easy to purchase and easily compatible with related accessories.

2) Reliable Performance

The zinc coating provides corrosion resistance, extending service life. It also boasts high tensile strength, ensuring structural safety, and excellent flexibility and ductility, making it easy to fabricate on-site.

3) Affordable

While offering reliable performance, it’s cost-effective and an ideal choice for large-scale projects.

Application

1. Fencing

It is commonly used as a woven material for zoo fencing and factory isolation fences, and can also be processed into temporary construction fencing. It is also suitable for making mesh for garden fences, such as when woven into diamond-shaped meshes for farm or private courtyard protection. It is also used as the backbone of wire mesh fencing and highway guardrails.

2. Construction and Bundling

In construction, it can be used to bundle rebar skeletons and steel pipes on scaffolding. In renovations, it can be used to bundle ceiling joists or pipe supports. During transportation, it can also be used to bundle construction waste or small building materials.

3. Agriculture and Horticulture

It can be used to build support frames for greenhouses; it can be used to make flower pot supports or climbing frames for vines, such as grape or bean trellises; it can also be used for orchard fencing or to secure fruit tree branches; and it can be made into poultry cages, such as chicken coops, rabbit cages, squirrel cages, and pigeon cages.

Bundling Scrap

Construction Bundling

Hay Binding

Hot Dip Galvanizing Process

Hot-dip galvanizing is our preferred method of applying a protective zinc coating to baling wire. Our manufacturing process uses the following 7-stage process:

1. Surface Preparation: Workers first clean the wire, removing impurities to ensure the zinc bonds uninhibitedly.

2. Pickling: Next, an acid solution removes the remaining oxides and scales, preparing the surface for reactivity.

3. Flux: A zinc chloride solution prepares the stripped surface before dipping and prevents oxidation risk.

4. Galvanizing Bath: The wire is then dipped into 450° C molten zinc.

5. Alloy Formation: The continued heat and zinc contact cause the iron molecules in the steel to diffuse into the molten zinc, forming a corrosion-resistant, overall metal coating.

6. Pull-out: The wire is gradually withdrawn, metering off excess liquid to achieve an even surface.

7. Quenching: The galvanized wire is rapidly cooled by a water jet, which quickly solidifies and locks the protective zinc barrier in place.

Wanzhi Steel offers several different grades of galvanizing. Our hot-dip process creates a thick, wear-resistant zinc coating that enhances the life and performance of your baler wire.

Why Choose Wanzhi Steel?

Your Reliable Supplier

As a professional steel wire manufacturer and exporter, we are committed to providing you with the highest quality products and services.

1) Wholesale Pricing

Our 1,000-square-meter factory boasts an annual production capacity of 300,000 tons. By eliminating middlemen, we offer highly competitive prices directly from the source.

2) Stable Quality

From raw materials to finished product, our stringent quality control system ensures consistent and reliable performance in every batch.

3) Customized Specifications

Flexible options are available, offering customized options with varying zinc coatings, tensile strengths, and coil weights.

4) Extensive Export Experience

Our expertise in international shipping and comprehensive export documentation ensures safe and timely delivery of your goods to your port.

Electro Galvanized Gi Iron Binding Wire

Galvanized wire for sale

Galvanized Wire Wholesaler

FAQ

Q: What is the specific diameter of 12-gauge steel wire?

A: According to the BWG/SWG standard, its nominal diameter is 2.77 mm. Different standard systems (such as AWG) have slight variations, so please confirm your desired standard before placing an order.

Q: Which is better for outdoor fencing: electrogalvanized or hot-dip galvanized?

A: For fencing exposed to the outdoors for extended periods, we strongly recommend hot-dip galvanized steel wire, as its thicker zinc coating provides decades of long-term protection.

Q: What is the minimum order quantity?

A: Our MOQ is 5 tons, which allows us to meet both large-scale projects and trial orders from small and medium-sized customers.

Q: Can you provide samples?

A: Of course. We provide small samples for testing so you can verify product quality. You only need to pay for shipping, which will be refunded after you place a formal order.

Standard Package

96 tons of galvanized wire shipped to Algeria

Galvanized wire coils shipped to Morocco

Wanzhi Steel-12 GA Galvanized Wire Wholesaler

12 gauge galvanized wire is the material of choice for many projects, offering good corrosion resistance, strength, and durability. Wanzhi Steel stocks a large range of 12 gauge galvanized wire in different coil weights and zinc coatings, and our 12 gauge galvanized wire has been put to use on projects in Brazil, Nigeria, Peru, Indonesia, Saudi Arabia, Türkiye, etc.

Get samples or a bulk quote! Chat with Us Online,

or send an email to: info03@wanzhisteel.com

Wanzhi Steel is an ISO 9001-certified steel factory located in Hebei, China. It has been specializing in the production of annealed wire, galvanized wire, low carbon wire, PVC-coated wire, Galfan Wire for 14 years, with a monthly output of 1,800 tons. With high-quality products and good services, its products have been exported to more than 120 countries around the world.

Leave Us A Message