5160 Steel

5160 Steel, also known as AISI 5160 or SAE 5160, is a high carbon and chromium spring steel (maximum carbon content 0.61%, chromium content 0.9%). It provides users with excellent toughness, high ductility, and excellent fatigue resistance. Alloy Steel 5160 is used in the automotive sector for a variety of different heavy spring applications, especially leaf springs. It is worth noting that Alloy Steel 5160 requires special procedures to weld and process.

China Aisi 1018 Astm A50 2mm A283 5160 (1)

Hot Rolled Galvanized Steel sheet A36 S355jr 5160

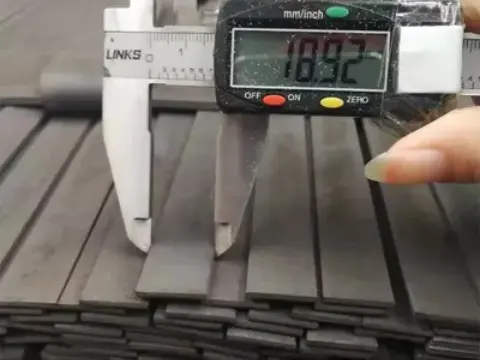

Sae 5160 Hot Rolled Flat Spring Steel

What is 5160 Steel?

5160 Steel is a high carbon alloy steel that belongs to the spring steel category. Toughness, durability, and resistance to deformation are typical characteristics. It is mainly used to manufacture various types of springs and cutting tools. According to the Society of Automotive Engineers (SAE) classification system, the “5160” number indicates the composition of the steel.

Chemical composition

| Elements | Content (%) |

| Iron, Fe | 97.085 – 97.84 |

| Manganese, Mn | 0.750 – 1 |

| Chromium, Cr | 0.7 – 0.9 |

| Carbon, C | 0.560 – 0.640 |

| Phosphorus, P | ≤ 0.0350 |

| Silicon, Si | 0.150 – 0.3 |

| Sulfur, S | ≤ 0.04 |

Mechanical properties

Mechanical properties are key indicators of how steel performs when subjected to stress.

The mechanical properties of 5160 steel are as follows:

The tensile strength (ultimate) is 724MPa (or 105000psi),

The tensile strength (yield) is 275MPa (or 39900psi).

The elongation after fracture (within 50 mm) is 17.20%, indicating that 5160 steel has good plasticity.

Brinell hardness is 197

The Vickers hardness (converted from the Brinell hardness) is 207.

Machinability (spheroidizing annealing and cold drawing. Based on 100% machinability of AISI 1212 steel): 55.

The welding performance is poor. This steel can be welded by arc or gas welding.

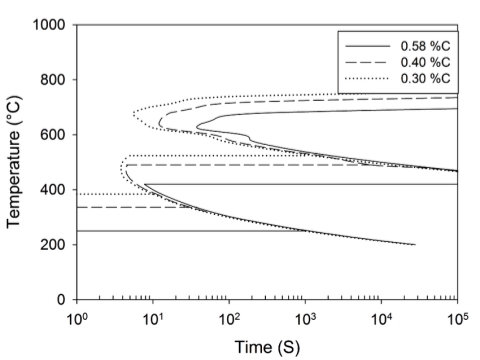

TTT-diagram-of-a-5160-steel

Hardness

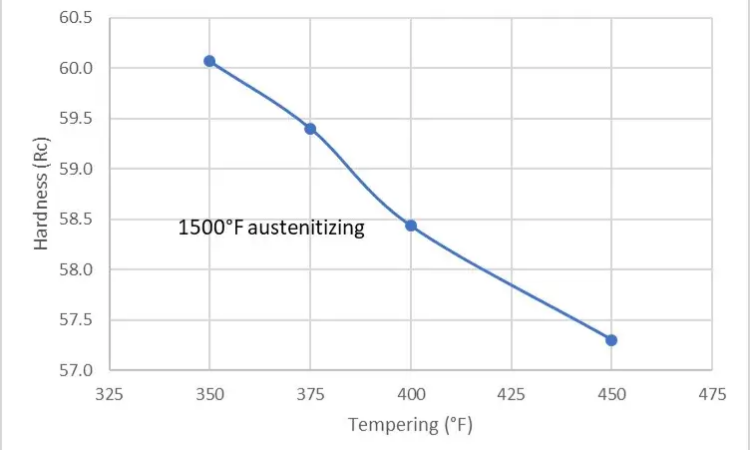

Minimum hardness is measured at minimum austenitizing temperature (1475°F). The hardness is relatively stable between 1500-1575°F, indicating that increasing the austenitizing temperature from 1475 to 1500°F dissolves more carbides, but there is no significant change above this temperature.

As a spring steel, 5160 is generally harder than standard carbon steel.

Physical properties

The physical properties of 5160 steel include density, elastic modulus, Poisson’s ratio, etc. Its density is 7.85 g/cm³ (or 0.284 lb/in³), its elastic modulus is between 190 GPa and 210 GPa (or between 27,557 ksi and 30,458 ksi), and its Poisson’s ratio is approximately 0.27 to 0.30.

5160_steel_grainsize_temperatures

5160-Hot-Rolled-Spring-Steel-l-Flat-Bar

5160 Alloy Steel Round Bar

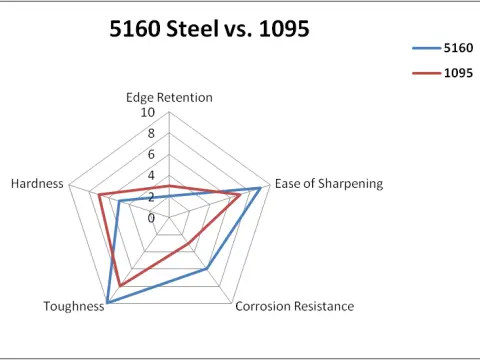

Is 5160 tougher than 1095?

The above answers what is 5160 steel, so what is 1095 steel? 1095 steel is a high carbon steel belonging to the category of carbon steel. It is famous for its relatively high carbon content and very low alloying element content. It is widely used in various cutting tools, especially knives, due to its excellent edge retention and sharpness.

So, in terms of toughness, 5160 is better than 1095 steel, and in terms of edge retention ability, 1095 is better, making sharpening a breeze.

Corrosion resistance of 5160 steel and 1095 steel

Both are essentially high carbon steel, unlike stainless steel, so they are prone to rust and corrosion when exposed to humid environments. Due to the difference in their chemical composition, their corrosion resistance is different.

5160 steel corrosion resistance: Chromium improves its toughness and hardenability, but it is still not as high as the chromium content of stainless steel, so its corrosion resistance is not as good as stainless steel.

1095 steel corrosion resistance: 1095 steel is an alloy steel with a high carbon content and does not contain important alloying elements such as chromium, so its corrosion resistance is not as good as 5160 steel containing chromium. When exposed to a corrosive environment, it is more likely to rust.

5160 VS 1095 steel

5160 steel vs. 1095 steel cost

1095 steel is a simpler alloy with a higher carbon content and missing chromium, so it is usually cheaper than 5160 steel. In general, the cost of raw steel is affected by factors such as production methods, alloying elements, and demand. You can consult our professional technicians for specific prices. This will help select steel that meets your expected performance and price.

Application

Mainly used in heavy industries such as automotive industry, machinery manufacturing, oil and gas, aerospace, etc. It is suitable for heavy cutting tasks, while 1095 steel is suitable for high-quality cutting, custom or handmade blades, and other delicate cutting.

For example: leaf springs, chisels and punches, agricultural tools such as plows and rakes.

High-strength bolts and fasteners, aircraft landing gear components, spring,s and shock absorbers. High-strength components such as drill pipes, pump rods, and pump shafts in oil fields.

Mainly due to its advantages of high strength, high elasticity, wear resistance,e and fatigue resistance.

Oil and Gas

Landing_Gear

e-spring-car

What is the difference between 5160 and 4340 steel?

5160 steel is known for its high tensile strength, which is usually higher than 4340 steel in the untreated state. It has good hardenability and low sensitivity to overheating. It is mainly used for springs that resist stress cycles, and also for tools and blades that combine toughness and wear resistance.

4340 steel can achieve very high tensile strength and yield strength after proper heat treatment. It maintains good toughness and shock absorption even at high strength levels. Compared with some other high-strength steel, it has excellent weldability and machinability, which is higher than 5160 steel. It is mainly used for gears, shafts, connecting rods, pump components, and pressure vessels with high strength and toughness.

Heat treatment characteristics

This includes quenching temperature, tempering temperature range, annealing, and forging.

Quenching temperature: usually 829°C (1525°F).

Tempering temperature range: between 427°C and 704°C (800°F and 1300°F).

Annealing: usually carried out at 788°C (1450°F) followed by air cooling.

Forging: carried out between 1149°C and 1204°C (2100°F and 2200°F).

5160-tempering-hardness

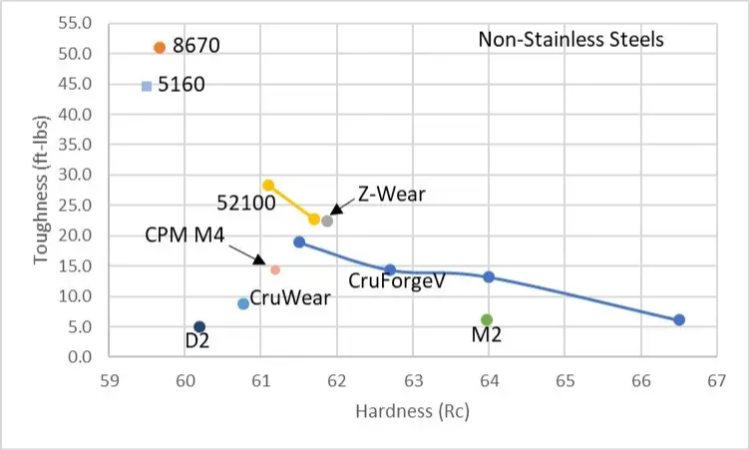

5160-toughness-non-stainless

What is 5160 steel equivalent to in the UK?

ASTM AISI SAE 5160 carbon steel is equivalent to European EN (German DIN EN, British BSI, French NF…), Chinese GB, and Japanese JIS standards. Wanzhi Steel provides Alloy Steel 5160 in different sizes and shapes, including rebar, round steel, bars, plates, strips, and coils.

Hot Rolled Black/GI Steel Flat Bar A36SS/400/S355jr/5160/1095/1080 Iron Carbon Mild Steel Metal Sheet Flat Bar Supply

Wanzhi Steel stocks a large inventory of carbon plate products for sale, from 2 to 20mm in thickness, and 600 to 3,000 in width. They are also available in different grades, including Q235, Q345, etc. Besides, we also provide various processing services including punching, bending, slitting, cutting, and other processing services. Welcome to contact us to know how we can meet your needs.

SAE-5160-Spring-Steel

S45c A36 S355jr 5160 1095 108 Ms Steel

AISI 5160 Spring Steel

If you have other questions, don’t hesitate to Get In Touch With Us.

( Inquire Online or send an email to Info03@wanzhisteel.com.)

Leave Us A Message