220 Tons of Galvalume Steel Coils Shipped to Brazil

In January 2026, we shipped 220 tons of aluminum-zinc coated steel coils to Brazil. This batch of Galvalume coils arrived at the Port of Santos in 11 20GP containers and will be supplied to local building materials processing plants for further processing.

Load onto truck

Container loading status

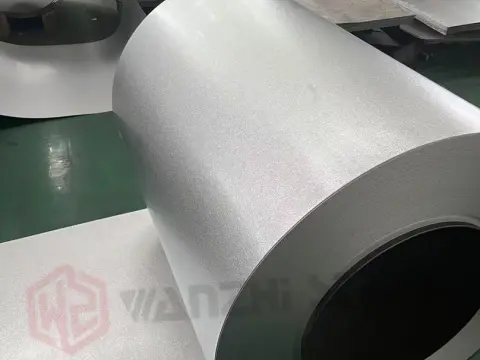

DX51D+AZ150 Galvanized Coil

Project Background

The client owns their own processing plant and had previously purchased our PPGI steel coils and galvanized coils. This latest purchase was for processing into roofing and wall panels for storage space in an industrial area. Due to the high temperature and humidity in southeastern Brazil, with an annual rainfall of 1500mm and slight acid rain, ordinary galvanized coils could not meet their long-term usage requirements. The client ultimately chose aluminized zinc steel coils to ensure a material lifespan of over 20 years and achieve a maintenance-free lifespan of at least 25 years.

Aluminized zinc coil production line

Order Specifications

1. Product: DX51D+AZ150 Galvalume Steel Coil

2. Standards: ASTM A792 / EN 10346 / Brazilian NBR 15575

3. Material: DX51D+AZ (S350GD+AZ)

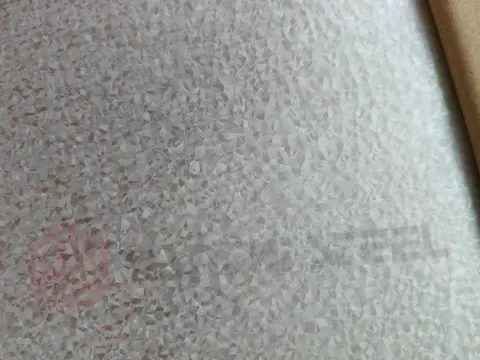

4. Coating Composition: 55% Aluminum + 43.5% Zinc + 1.5% Silicon

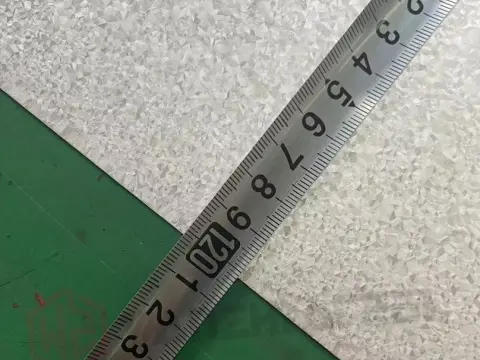

5. Thickness: 0.4mm–0.6mm

6. Width: 1200mm

8. Inner Diameter: 508mm

9. Zinc Coating Weight: AZ150 (150g/m²)

10. Surface Treatment: Passivation + Oiling, Anti-fingerprint

11. Total Order Quantity: 220 tons

12. Single Coil Weight: 5–7 tons/coil

13. Packaging: Export standard moisture-proof and rust-proof packaging (inner rust-proof paper + outer waterproof PE film + steel strap reinforcement)

14. Container Loading: 11×20GP containers (20 tons per container) (tons)

15. Transportation: Sea freight to Santos port

Our Solutions

1. Customized Aluminized Zinc Coating Process

Utilizing a continuous hot-dip galvanizing production line, we strictly control the aluminum-zinc ratio and coating thickness to ensure the product’s corrosion resistance and high-temperature performance, adapting to the complex climate of Latin America.

2. Certification Reports

We provide SGS test reports to ensure product compliance with local construction industry standards (NBR 15575), facilitating rapid customer acceptance.

Neat edges

1200mm Width

0.6mm thick Galvalume Steel Coil

3. Professional Packaging

For 35-day long-haul sea freight, we use multi-layered moisture-proof and rust-proof packaging, placing desiccants inside the containers to prevent rust.

4. Efficient Logistics

We complete booking and loading according to schedule, ensuring all containers are loaded and shipped on time and arrive smoothly at the customer’s site.

Quality Control

1. Raw Material Control

Hot-rolled substrates from top-tier steel mills such as Baosteel and Ansteel are used to ensure product stability from the source.

2. Coating Monitoring

Online X-ray fluorescence thickness gauges are used to ensure coating uniformity.

3. Performance Testing

Each coil is sampled and passes the salt spray test (ASTM B117). Mechanical property tests include a yield strength of≥350MPa and a tensile strength of≥420MPa.

S350GD+AZ150 Surface

Coil diameter measurement

Coating thickness inspection

Customer Feedback

Upon receiving the goods, the customer immediately conducted testing: no coating peeling was observed in the T-bend test, fingerprint resistance passed the 72-hour humidity test, and no plating peeling occurred during local roll forming, fully meeting processing and usage requirements. He decided to recommend us to his business partners.

Economic Analysis – Galvanized Steel Coil VS. Galvalume Steel Coil

| Comparison Items | Aluminized zinc-coated steel coil | Galvanized steel coil |

| Initial Cost | 15-20% higher | Benchmark |

| Expected Lifespan | 25-30 years | 10-15 years |

| Total Cost | Lightness maintenance every 8-10 days | Anti-corrosion treatment is required every 3-5 years. |

| Over 25 Years | Approximately 35% lower | Benchmark |

Regular Spangle galvanized coil

galvanized steel coil wholesaler

Aluminum-zinc coated steel coil manufacturer

Why Does The Brazilian Market Choose Aluminized Zinc Coils?

1. Climate Adaptability

Its corrosion resistance is 2-6 times that of galvanized products. It possesses self-healing capabilities for cuts and scratches and can withstand temperatures up to 600℃. Perfectly suited to the tropical-subtropical climates and harsh coastal environments of South America.

2. Compliant with Local Building Codes

All performance indicators fully meet the stringent durability requirements of the new Brazilian building standard (NBR 15575), allowing for compliant use without additional modifications.

3. High Cost-Effectiveness

Although the initial cost is slightly higher, the longer service life and extended maintenance intervals result in lower overall costs.

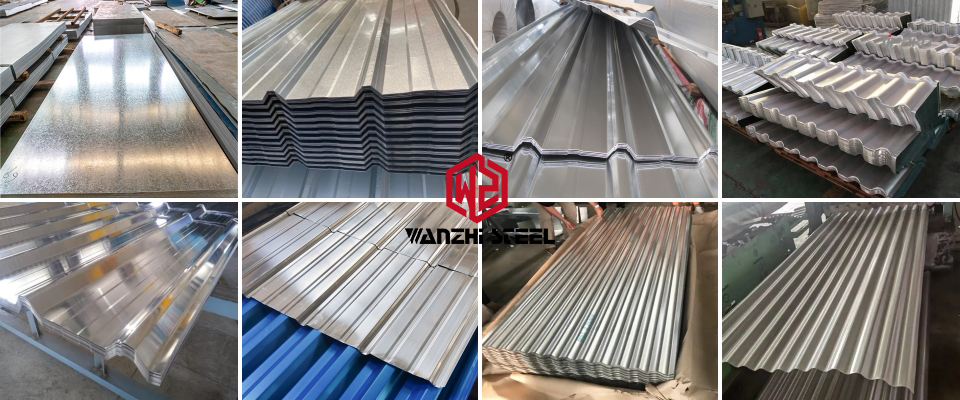

Customer-processed roofing panels, Galvalume corrugated panels

If you are also interested in galvalume steel coil & sheet, please contact Wanzhi Steel.

Consult Now:

Official web: https://wanzhifence.com

Email: info03@wanzhisteel.com

Our WhatsApp: 8613938459717

Leave Us A Message